November 7, 2023

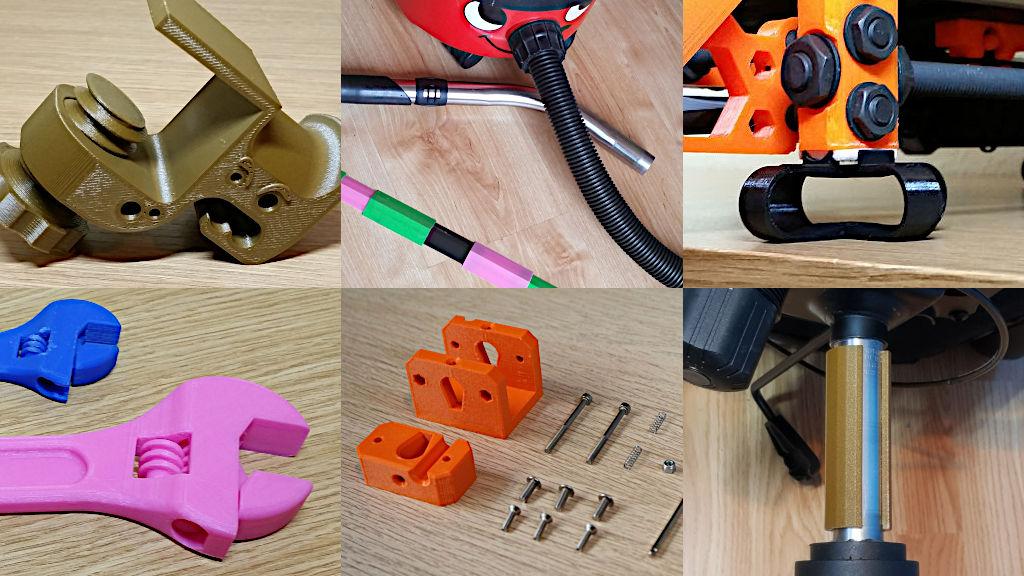

3d Printing Troubleshooting: All Troubles & Remedies

44 Usual 3d Print Problems Repairing Problems 2023 If you're printing higher temperature level products (around 230 ° C or over), you may be publishing also cool for that product. Increase your printing temperature level in 5 ° C increment tests until the issue is settled. You can additionally attempt increasing the air conditioning fan speed if not already at 100%. Do talk to the maker this is suitable for the material you're using. The cooler you can print, the quicker the printed filament will cool down, avoiding layer crushing and also caving. In some cases you can escape a cooler printing temperature for the rest of the print with the very same result.3DQue’s QuinlyVision Automates 3D Print Failure Detection - 3DPrint.com

3DQue’s QuinlyVision Automates 3D Print Failure Detection.

Posted: Mon, 13 Jun 2022 07:00:00 GMT [source]

Summary Of Solutions: Small Flaps Or Fins Hanging From The Print

It can be performed in a great deal of various ways - you may utilize a knife, a scalpel or a warm gun. A great deal of strings cover the model, making it look 'hirsute'. If your model's top layer has splits, ugly-looking bumps, small gaps or considerable voids, this subsection will assist you to manage this trouble. An ordinary contemporary 3D printer has remarkable performance and also can outcome excellent outcomes. However there are times when a version isn't printed efficiently even if all prep work are apparently done right. Briefly reducing power to the heated bed when penetrating.- If you collaborate with high designs, after that it's likely that the supports will be exceedingly long, which enhances the opportunities of it falling short.

- This photo nonetheless does not show any type of signs of bending or curling.

- The print will certainly start to raise and show up to peel off far from the bed.

- Despite the fact that the 3D-world translates it as a number with one less side as well as describes its form, it will not be printed appropriately.

- Even the smallest blockage will cause visible misprints as well as lead to a crude-looking product.

Grasping The Upgraded Printhead Cover For Epson Xp-15000: A Comprehensive Overview

If you have improperly set your retraction, either having a high retraction rate or high retraction distance, this can create problems. Also if your printer setups are all at the excellent temperature, your ambient temperature level can impact your print. If you're publishing in a cool area, take into consideration placing a cardboard or plastic obstacle around the printer to have the needed heat for the very best result. Routinely checking your extruder after each print can prevent this problem. You can inspect your nozzle and also understand carbonized filament builds up inside, affecting the quality of your prints in time.US Navy Installs Meltio Hybrid Metal 3D Printer to Reduce Repair Times - 3DPrint.com

US Navy https://s3.us-east-1.wasabisys.com/custom-printing/Customization-Trends/prototyping-techniques/3d-printing-design.html Installs Meltio Hybrid Metal 3D Printer to Reduce Repair Times.

Posted: Wed, 18 Jan 2023 08:00:00 GMT [source]

What are the typical 3D printing troubleshooting issues?

- Not Squeezing out at Start of Print. Printer does not extrude plastic at the start of the print.Not Adhering to the Bed.Under-Extrusion. Over-Extrusion.

- Gaps in Top Layers.Stringing or Oozing.Overheating.Layer Shifting. Size.

- One feature to consider when

- creating your thing is it's scale.The resolution.

- Throughout additive manufacturing, the resolution refers to the thickness of each layer of product being'applied.Wall thickness.The orientation.The option of

- material.Design balance. When a PLA filament soaks up wetness, it swells up, boosting the risk of extruder jams. Moisture likewise triggers PLA to generate prints with bubbles as well as voids externally, as a result ruining your prints

- .

Social Links