November 22, 2023

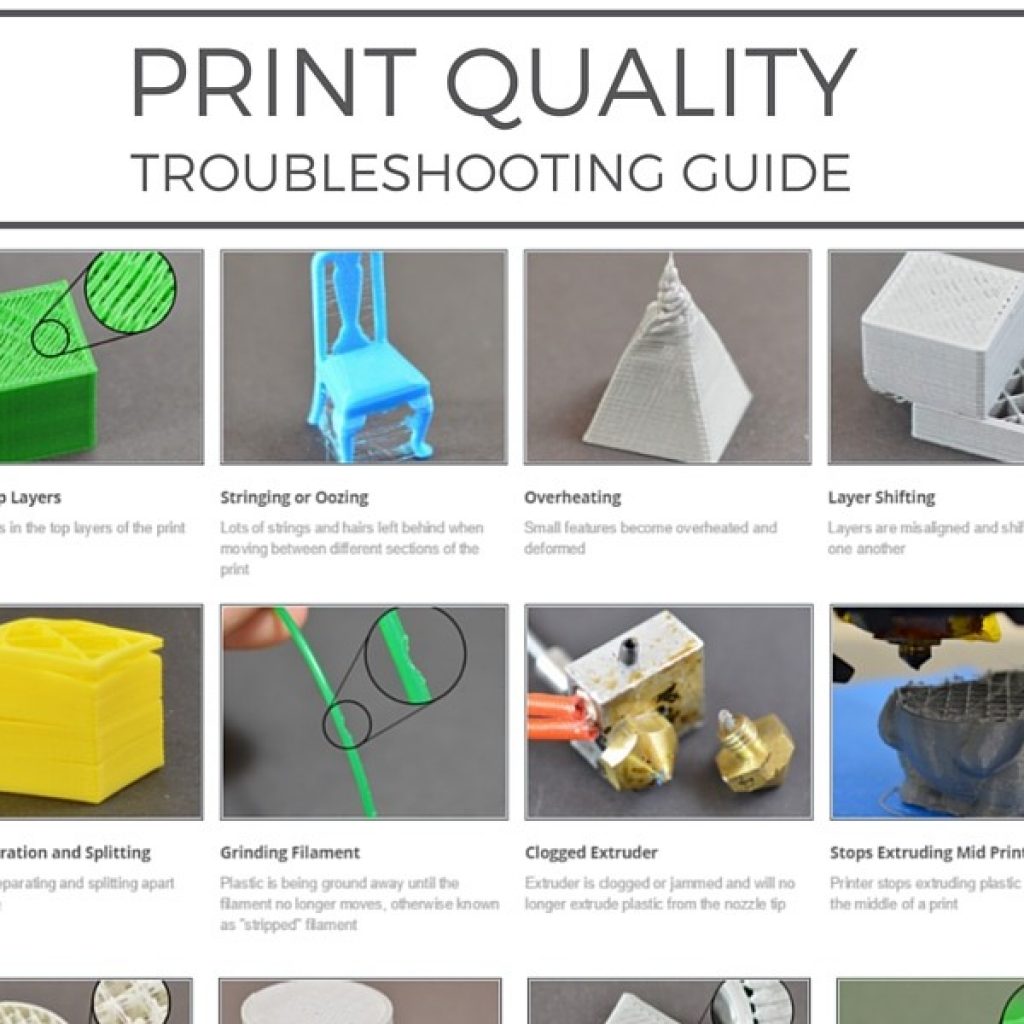

7 Most Usual Problems With A 3d Printer Exactly How To Fix

Troubleshooting Overview You're here because you have actually either just had a full 3D print failing, or your prints aren't rather ideal. We do not settle for much less than best, so we don't expect you to either. Have you ever before experienced a layer change in your 3D prints? Learn just how to identify and also take care of layer change in 3D prints prior to they come to be an issue. Today's selection is the substantial Articulated Dragon by Cults contributor MCGYBEER and printed to range by Metalhead Printing.3DQue’s QuinlyVision Automates 3D Print Failure Detection - 3DPrint.com

3DQue’s QuinlyVision Automates 3D Print Failure Detection.

Posted: Mon, 13 Jun 2022 07:00:00 GMT [source]

Recap Of Remedies: Unpleasant Very First Layer

It can be done in a great deal of different ways - you might make use of a blade, a scalpel or a warmth gun. A great deal of strings cover the version, making it look 'hairy'. If your model's leading layer https://devclouds.blob.core.windows.net/dimensional-dynamics/navigating-common-challenges-at-3d-printing-conferences/index.html has fractures, ugly-looking bumps, tiny spaces or considerable voids, this subsection will certainly aid you to take care of this problem. The wearing of the interface layer is difficult to prevent, as well as its repercussions like ghost marks and also general reduction of item quality. Extreme wearing makes specific print plate areas to end up being completely unsuitable for printing. The primary services are to either buy a brand-new user interface layer, substitute the layer you currently use with a self-made one or get a brand-new barrel. You might likewise just keep transferring your prints until there disappears areas ideal for printing. One more factor that has a fantastic influences over the level of print's attachment is appropriately ready print plate. In case of bottom-up SLA printers, the very best decision is to manufacture your models onto a carefully textured degree metal plate.- If there's no material to utilize, the printer won't function, so you can put a new spool and also try to rerun the print.

- It lowers exactly how quickly the model cools off given that the temperature level around the extruded filament is greater.

- Check the strength as well as proper positioning of your printer framework.

- Some extra lines of filament can trigger your print to look various than it should.

- The first thing to do if you experience over extrusion is to lower your printing temperature level so filament does not move with so quickly.

Bltouch/ Abl Probes

You're HotEnd could be absorbing air, despite the fact that this is generally more of a whistle than a pop. If you do not have the correct settings for the linking required, then you will experience droopy lines and also inadequate bridging. If you discover on your own suffering from this trouble a whole lot, you might want to consider getting a double extrusion system. If the space is as well close, breaking short the assistances will certainly harm the surface of your real things. You can try doing a few of your own tests by raising your bed temperature by 10 ° C and seeing the results. You want to take care of bending or crinkling if it takes place in your 3D prints because it can cause failed prints or dimensionally incorrect models. You may also want to inspect the high quality of your filament. In time, it can gather wetness, which raises the probability of stringing. Printing at a lower temperature minimizes the possibility of stringing. Given that the filament isn't obtaining as warm, it's much less most likely that recurring warm strings will curtain between features. Component cooling down fans ought to not reach more than 10-20% with ASA. A cozy ambient temperature is ideal however that does not suggest print at the hottest temperature level within the range. Try minimizing your printing temperature if you experience over heating with ASA. 3D printer stringing as well as nozzle oozing are two typical 3D printer problems that generally share the very same origin.How do you know if PLA filament misbehaves?

Social Links