November 7, 2023

Additive Production 3d Printing Niosh

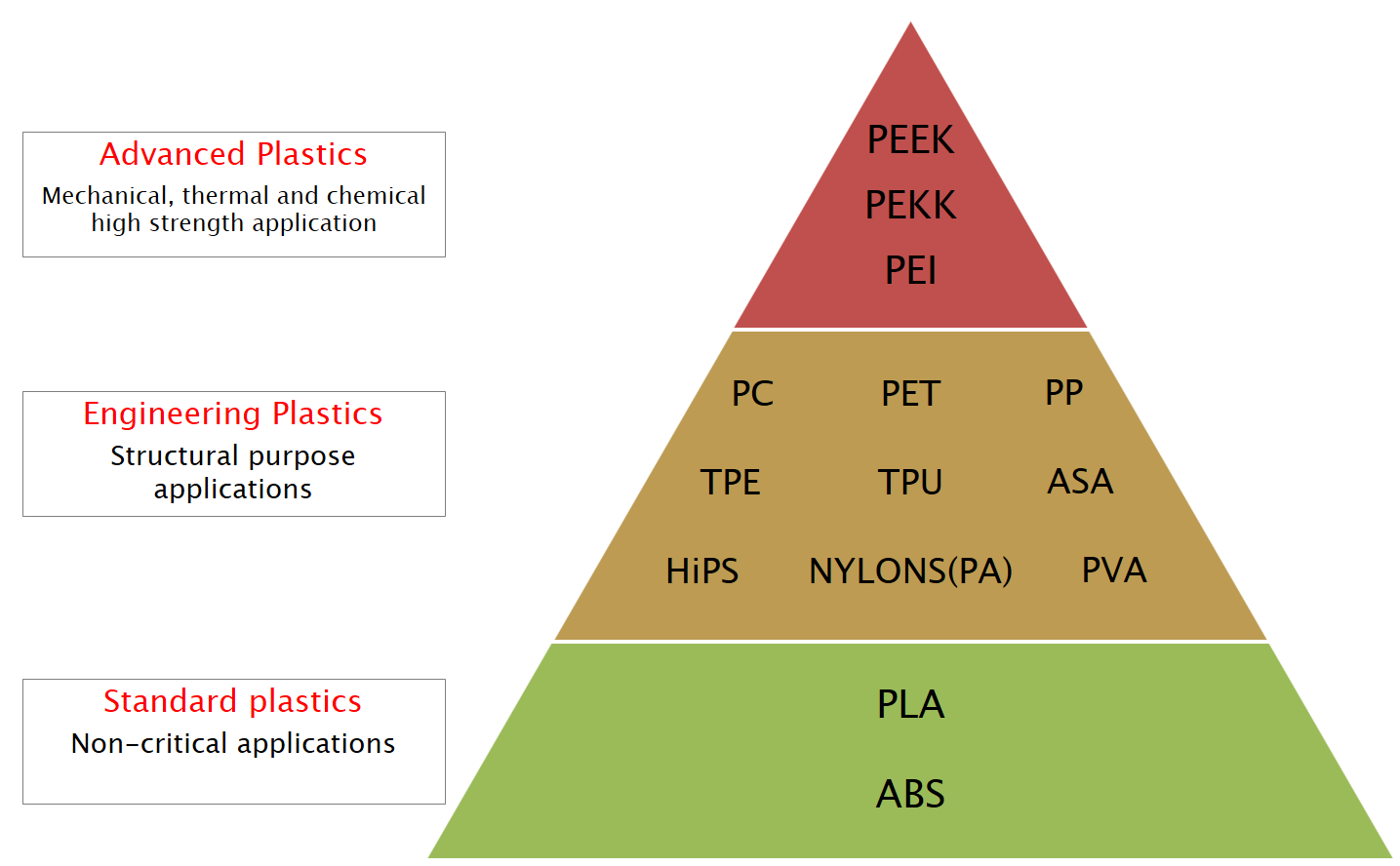

3d Printing Strategies: Various Types Of 3d Printing When examining prospective manufacturing companions, companies take a large range of standard right into account. Style capabilities cover the checklist yet capability to range, rates and experience all comply with very closely behind. When it pertains to primary use, the inconsistency between plastic and also steel 3D printing isn't as huge as you might assume. Greater than a 3rd of participants responded to that they use plastics and metals similarly, as well as also in between those that selected either plastics or steels, plastics led by just a little over 10%. When we conducted our very first survey, most of the benefits were still intangible ideas.What is the innovation of 3D printing?

Innovations in 3D printing have made it less complicated for designers and also engineers to personalize tasks, create physical models at various ranges, and produce structures that can not be made with even more conventional manufacturing strategies.

Discerning Laser Sintering (sls):

The binding material burns away and the steel powder joins right into a full steel component. This process can be carried out in sets, suggesting that it doesn't substantially influence throughput. The technology behind steel binder jetting shows what a standard printer makes use of to swiftly jet ink onto paper. First, a binder jetting device equally distributes steel powder over its print bed, creating an unbound layer. Then, a jetting head similar to one in a 2D printer distributes binding polymer in the form of the part cross section, freely sticking the powder. Too little direct exposure might result in inadequate smoothing, while excessive exposure can cause the part to end up being deformed or weakened. Normally, the vapor smoothing process takes between 10 and also 60 mins, depending upon the material, the solvent, and the desired surface. [newline] FFF is one of the most optimal approach of quick prototyping of components which must keep the conventional resistance. The approach has actually been extensively utilized in developing building or model mock-ups. At one factor he states 11 ideas, but the title has 10 as well as we had to extend to get to that number considering that some of them have some overlap. However, he likewise reveals some C-clips, a technique to add walls for strength, as well as printing spur gears. NIOSH is conducting research on secure additive production to determine knowledge spaces, to create robust scientific research essential to advance understanding in the field, and to ideal apply these advancements in order to secure https://s3.us-east-1.wasabisys.com/custom-printing/Customization-Trends/prototyping-techniques/recent-developments-in-3d-printing-of-biomaterials-journal-of-organic-design.html the American worker. Facial exposure to harmful products is feasible, especially with those in powdered or fluid form. Additive production hazards differ commonly relying on the modern technology as well as products utilized. In that circumstance, 3D parts making with a 3D printer can be a lifesaver. 3D printing may still appear advanced, yet it's currently contributing in producing operations today, producing parts that fold up effortlessly right into supply chains worldwide. To read more concerning 3D printing applications in manufacturing and also the means 3D printing can assist your legacy devices, contact us.Published Structures

A lot of what we publish often tends to be units and there are some great ideas for those floating about. But if you are just beginning, you should check out's video of points he wished somebody had actually told him when he began 3D printing. Preparing a component for a develop is greatly automated with some hand-operated communication to ideal component alignment or assistance creation.- For SLS printed steel parts, warmth therapy is a vital post-processing action to improve their mechanical properties and eliminate inner stresses.

- Considering that rastering a laser light beam can be sluggish, especially for huge components, the covered up lamp technique was created to treat an entire layer of photopolymers at once.

- Discover everything about the opportunities of just how additive manufacturing makes your production much more reliable.

- LOM is rapid and optimal for making big prints however the surface finish is harsh.

- By fertilizing the part with a low-viscosity material, such as epoxy or cyanoacrylate, the component's porosity can be reduced, causing increased stamina, tightness, and a smoother surface finish.

3D Printing Advanced Technology Center Opens in Japan to Spur ... - All3DP

3D Printing Advanced Technology Center Opens in Japan to Spur ....

Posted: Wed, 26 Apr 2023 07:00:00 GMT [source]

Social Links