November 22, 2023

3d Printer Suggestions And Methods

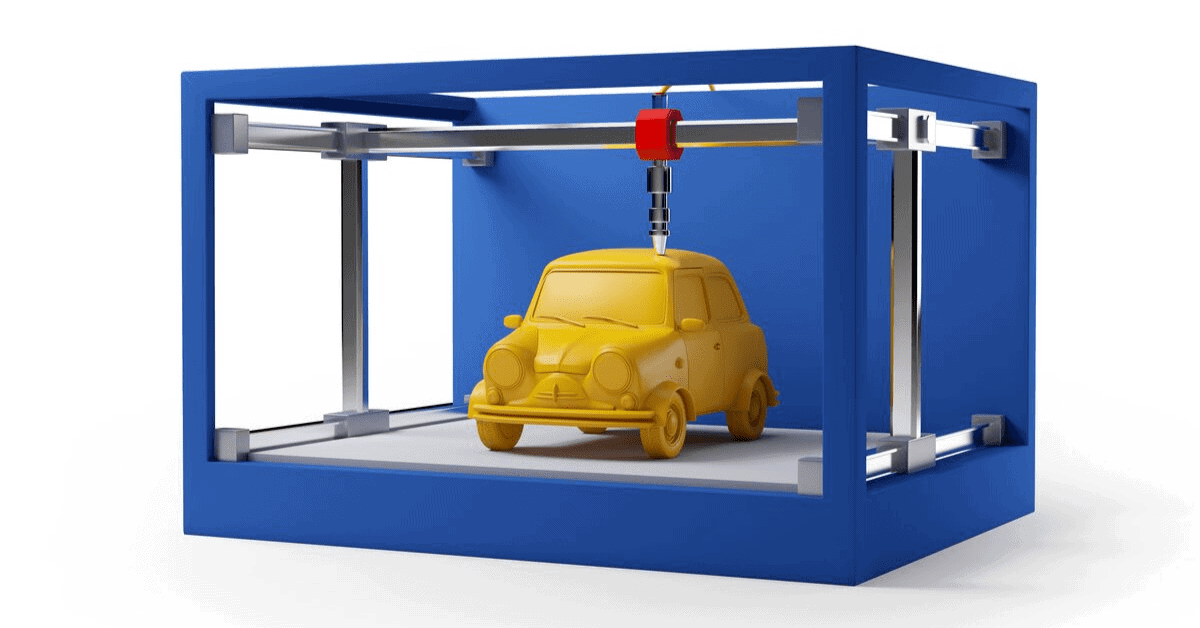

3d Printing Methods: Different Types Of 3d Printing Support removal is another essential post-processing step for SLA printed parts. Unlike dual-extrusion FDM 3D printers, SLA printers constantly produce supports made from the exact same material as the published component, and also removing them needs cautious cutting or damaging to stay clear of harming the part. When the assistances have been gotten rid of, any continuing to be support marks can be sanded or filed down to make certain a clean surface area coating. By utilizing progressively finer grits of sandpaper, you can minimize the presence of layer lines as well as ravel support marks on the component's surface.What is the toughest 3D printing method?

Polycarbonate. According to several manufacturers as well as customers, polycarbonate (PC) is considered the best consumer filament available. Computer can yield extremely high-strength parts when printed correctly with an all-metal warm end and also a room.

Publishing Fads: 6 Major Growths

The binding material burns away and the steel powder joins into a full steel part. This process can be done in sets, meaning that it does not substantially impact throughput. The modern technology behind metal binder jetting reflects what a traditional printer uses to promptly jet ink onto paper. First, a binder jetting machine evenly distributes steel powder over its print bed, creating an unbound layer. After that, a jetting head just like one in a 2D printer disperses binding polymer in the form of the component sample, freely adhering the powder. The drop-spread-print cycle is repeated until the whole component is finished. The local structure can be manipulated by specifying the ideal printhead to deposit the predetermined quantity of the ideal binder. The regional microstructure can be regulated by modifying the printing criteria throughout construction. The unification of micro-channels properly distributed extra seeding surfaces throughout the inside of the device, boosting the effective seeding density and harmony. Patterned surface chemistry possibly uses spatial control over cell circulation of multiple cell kind. This modern technology is limited by the competing demands in between printhead dependability and attribute resolution, as small nozzles can make better functions but are much more vulnerable to clogging. Among the main goals of post-processing is to enhance the appearance of published items. As an example, the FDM 3D printing process produces noticeable layer lines on the surface of components, interfering with their general aesthetic quality. However post-processing methods such as sanding, polishing, as well as painting can successfully eliminate or minimize these lines, leading to a smoother as well as a lot more professional-looking coating. In 2003, Rupert Soar secured funding and also created the freeform building team at Loughborough University, UK, to check out the capacity for up-scaling existing 3D printing strategies for construction applications. In 2005, the group secured funding to develop a large-scale building and construction 3D printing machine making use of 'off the shelf' components to explore how complicated such components might be and realistically fulfill the needs for building and construction. Steel 3D printing is extensively utilized for models and also end-use components in the aerospace, clinical, power and auto sectors. As expenses decrease as well as part dimensions enhance, metal 3D printing is positioned to end up being much more extensively embraced for production. 3D Printing assures to generate complicated biomedical gadgets according to computer design making use of patient-specific anatomical information.Recent Developments In 3d Printing Of Biomaterials

Voxeljet is just one of the pioneers when it involves developing 3D production procedures in the industrial setting. As of September 2020, revenue sales for devices extruding polymers were most popular, adhered to by those for powder bed combination of steels. By contrast, smaller nozzles down payment material with better resolution, yet present techniques with conventional software program are as well sluggish to be economical. Rutgers designers have actually developed a method to 3D print huge and complex components at a fraction of the expense of current approaches. For several years in many items and also applications a secure hash formula authentication plan has been an extremely reliable way to protect IP from counterfeiting as well as illegal duplicating.- The accuracy of the technology of less than 0.099 mm might not be matched by any various other additive innovation.

- Lam et al. produced starch-based scaffolds by printing pure water, showing the expediency of using biological agents and living cells during construction.

- Distributed 3D printing might eventually transform economies as well as standard of lives in linked cultures around the globe.

- As opposed to standard procedures, the binder is processed inline in the equipment with pinpoint accuracy.

- Ideal to make styles rapidly comprehensible and also to be able to analyze them carefully from every perspective without much effort.

Making Battery Products With Ultrasmall Structural Functions

Soluble supports are short-lived structures utilized to support overhanging functions throughout 3D printing. After printing, the assistances are dissolved away utilizing a solvent, leaving behind the finished component. Publishing with soluble supports enables you to produce much more intricate geometries. • Stereolithography-- SLA uses an ultraviolet laser to heal a photosensitive material right into set plastic.Advanced 3D Printing Tips - Hackaday

Advanced 3D Printing Tips.

Posted: Fri, 17 Mar 2023 07:00:00 GMT [source]

Social Links