November 7, 2023

3d Printing Innovations: Types As Well As Benefits

New 3d Printing Technique Ready To Progress Manufacturing For each technology, recent advancements in machine ability as well as biomaterials will be examined. Exactly how new additive 3D production processes are advancing tomorrow's airplane design. At the very same time, manufacturing efficiency and also making rate are significantly coming to be the focus of aircraft makers and also their distributors. Depending upon consumer demands, voxeljet 3D printers can be integrated right into manufacturing processes as stand-alone systems or as partially or fully automated devices. Voxeljet supports the combination procedure along with process and automation experts from a variety of industries. However with the raised use as well as applications we have actually observed in the last few years, these are currently confirmed truths, as well as study individuals are much more fired up concerning the advantages of additive than they were 2 years back. We've detailed the leading three benefits firms report delighting in thanks to additive manufacturing. Download the 2021 survey report to learn more about the current state of the global 3D printing market. The principle is to substantially reduce the paths of the ions inside the battery throughout the charging process. To do this, the electrodes, which are presently flat, would certainly have to have a three-dimensional surface area framework.What Are The Benefits Of 3d Printing?

After cleansing, the hard copy is positioned in a speciality light-setter where the resin versions obtain their last residential properties. Whether being utilized for building useful quick models, for small/medium series manufacturing, or for large-scale series manufacturing, 3D printing offers considerable benefits over conventional production. Xometry makes no depiction or guarantee of any type of kind, be it shared or suggested, as to the accuracy, completeness, or legitimacy of the information.3D Printers Were Never Going To ‘Save’ Manufacturing, But Here’s How They’re Quickly Becoming An Industry 4.0 Staple - Forbes

3D Printers Were Never Going To ‘Save’ Manufacturing, But Here’s How They’re Quickly Becoming An Industry 4.0 Staple.

Posted: Mon, 15 May 2023 07:00:00 GMT [source]

-- Product Extrusion

We provide extensive assistance, starting from a layout and also 3D modelling, with the option of an appropriate 3D printing innovation, and also ending with painting as well as final ending up of the all set hard copy. An effective laser is made use of in 3D printing to fuse metals as well as alloys on a mini scale. The primary applications of DMLS include the development of metal components of complex geometry. Right after the 3D printing procedure the parts are completely functional (heat-resistant, strong and also long lasting). Actually, the components are also better than those cast with regard to thickness, and that converts right into their mechanical residential properties.What are the 3D printing techniques?

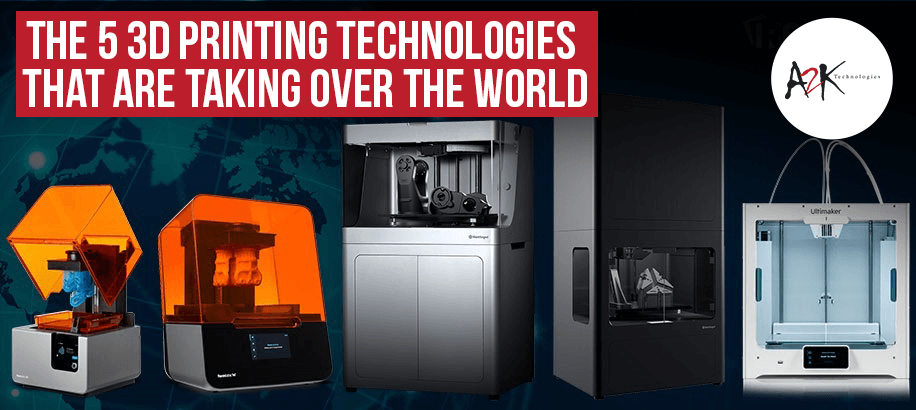

There are a number of sorts of 3D printing, that include: Stereolithography (RUN-DOWN NEIGHBORHOOD) Careful Laser Sintering (SLS) Integrated Deposition Modeling (FDM).

Has The 3d Printing Change Lastly Gotten Here?

While SLS parts typically have a rougher surface than run-down neighborhood or FDM parts, sanding can help remove blemishes as well as create a much more uniform finish. Progressively finer grits of sandpaper can be utilized to attain the wanted surface smoothness. For steel SLS components, polishing can be https://us-southeast-1.linodeobjects.com/custom-printing/Packaging-Design/design-principles/kinds-of-3d-printer.html utilized to accomplish a mirror-like finish. After cleaning, SLA printed components might call for post-curing, which includes subjecting the component to UV light to fully heal the remaining material and also ensure ideal mechanical residential properties. Post-curing can be carried out using a specialized curing chamber or by placing the component under direct sunlight. The period as well as intensity of UV exposure need to be readjusted according to the certain material used as well as the end-use of the final part.- The assimilation of SFF innovations with patient-specific medical imaging information makes it possible for the aseptic production of tissue design grafts that match specifically to a client's contours can be produced by.

- It is essentially mould-free injection molding of last frameworks, making it practical to make distinctive, one client at a time clinical device.

- Yet when those obstacles are overcome-- or eased-- passion in various 3D printing products is high.

- Additive manufacturing systems build any component one layer each time as well as bring a lengthy listing of advantages to the table.

Social Links