November 22, 2023

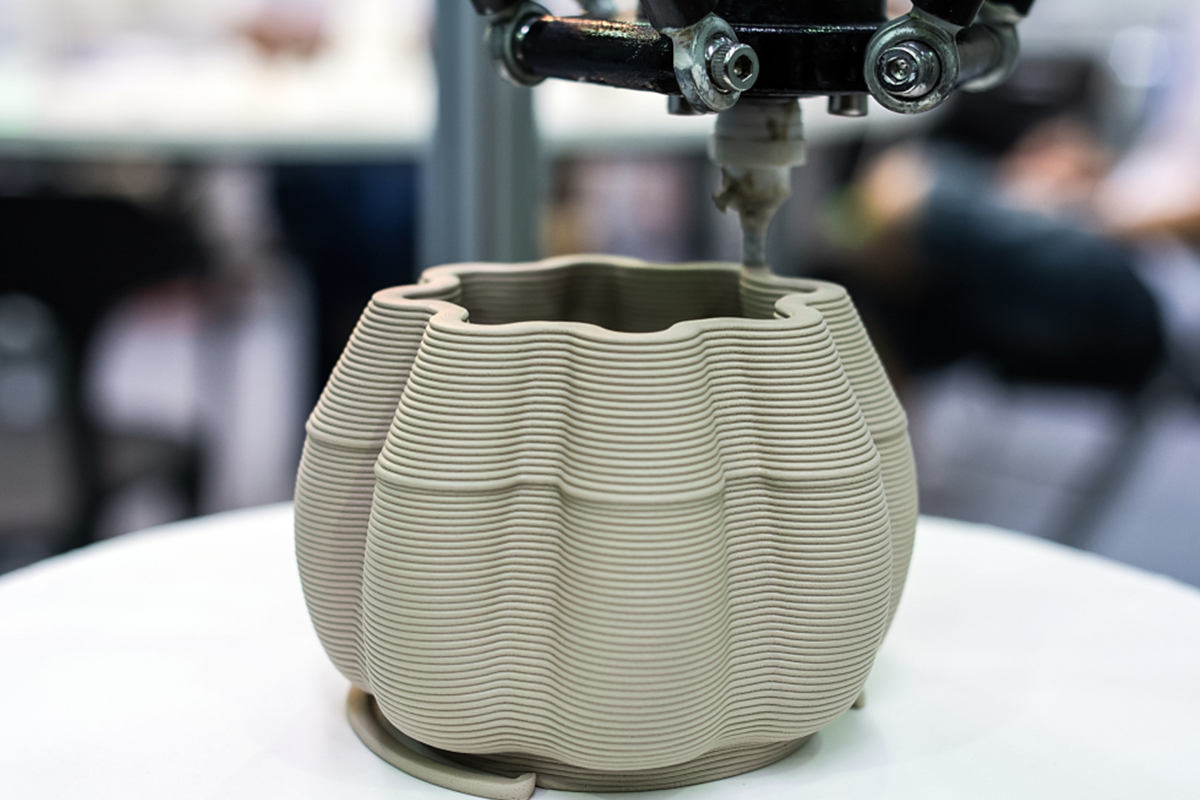

New 3d Printing Strategy Ready To Advance Production

New 3d Printing Procedure Is Faster And Much More Specific Than Standard Approaches Sciencedaily Numerous companies are currently offering 3D printed clothes as well as shoes as retail products. 3D scanning is the procedure of evaluating a real-world object to collect information on its shape and also appearance. The scanned information can after that be made use of to publish a replica of the things on a 3D printer. A version of Kyiv's Saint Sophia Cathedral in the blue and yellow of the Ukrainian flag, used the iCLIP approach for 3D printing, which enables using numerous types-- or colors-- of material in a single object. As soon as the surfaces are prepared, they are straightened and brought right into close get in touch with, typically with a void of no more than a few nanometers. Stress is then put on the components, compeling the surface areas with each other and causing the steel atoms to come together and bond. The magnitude of the employed stress and also the period of the process depend on the specific product properties and the wanted stamina of the bond. Similarly, transforming procedures can be employed to improve round or in proportion elements, ensuring that their measurements meet the called for specifications. Grinding, on the various other hand, is utilized to accomplish ultra-fine surface finishes as well as high-precision geometries, such as those needed for securing surface areas or birthing elements.The Trouble Of Power Storage Space Is Facility

Perfect to make styles promptly comprehensible and to be able to analyze them thoroughly from every perspective without much initiative. Despite whether the individual instance includes item layout, carefully in-depth building designs or high-resolution movie props. With an adjoining footprint of 4 x 2 x 1 meters, it is unrivaled in terms of develop volume. In spite of your high-volume manufacturing work, the VX4000 makes sure consistent develop times and outstanding precession and component top quality.3D Printers Were Never Going To ‘Save’ Manufacturing, But Here’s How They’re Quickly Becoming An Industry 4.0 Staple - Forbes

3D Printers Were Never Going To ‘Save’ Manufacturing, But Here’s How They’re Quickly Becoming An Industry 4.0 Staple.

Posted: Mon, 15 May 2023 07:00:00 GMT [source]

When Were 3d Printers Introduced?

High throughput printing of single-cell arrays has been revealed with "Block-Cell-Printing". Caught cells can be combined as well as separated 5 μm to research cell interaction. In this study, entraped main rat cortical nerve cells were cultured as well as cells exhibited neuronal morphology.What is the improvement of 3D printing?

Advancements in 3D printing have made it simpler for designers as well as designers to tailor jobs, create physical prototypes at various ranges, and generate structures that can not be made with even more typical production methods.

- The list of study projects is broadening a lot more in the last number of years, many thanks to an expanding rate of interest in the field.

- Each private layer is functionally 2-dimensional; it just creates a complex 3D form by printing lots of succeeding layers.

- Nevertheless, they still require post-processing to accomplish the desired look and also mechanical residential or commercial properties.

- System designers have actually made use of the DS28E15 to secure their R&D investments due to the fact that this authenticator implements sophisticated physical safety as well as supplies the best in inexpensive IP protection.

Social Links