November 7, 2023

The Supreme Guide To 3d Printing Post-processing Strategies

3d Printing Trends: 6 Significant Advancements After curing, the mold and mildew is after that either crushed or melted, with the wax filtered and also recycled, substantially minimizing waste, as compared with conventional mold technologies. The benefits of the modern technology are its quick mold and mildew fabrication, enhanced production performances, minimized labor, and also online elimination of waste through product reuse for bespoke molds. The system was later on adjusted to integrate with a five-axis, high-speed gantry to accomplish the rapid surface-milling tolerances, needed for the system.What are the 3D printing methods?

There are several kinds of 3D printing, which include: Stereolithography (RUN-DOWN NEIGHBORHOOD) Discerning Laser Sintering (SLS) Merged Deposition Modeling (FDM).

Pointers To Boost Your 3d Printing Abilities

Fast prototyping with 3D printing takes the guesswork out of new item style. A specific and promptly created model connects in a manner that a CAD drawing never ever can. A second column is the comprehensive exposure assessments have actually been performed by the NIOSH Nanotechnology and also Advanced Products Field Studies Teamat 10 different additive production sites. Fieldwork allows NIOSH to fill expertise voids on real-world technologies, uses, and exposures. Please reach out to us if you are interested in finding out more info or having this team visit your facility. At the very same time, its potential to alter the production of medical items-- specifically high-risk tools such as implants-- could affect patient safety and security, producing brand-new challenges for Fda oversight. Breakthroughs in 3D printing, additionally called additive production, are capturing interest in https://nyc3.digitaloceanspaces.com/custom-printing/Printing-Techniques/car-wrap-design/print-top-quality.html the healthcare area as a result of their possible to enhance treatment for sure medical conditions. A radiologist, for example, might develop a specific replica of a client's spine to aid plan a surgical treatment; a dental professional can scan a broken tooth to make a crown that fits precisely right into the person's mouth. In both instances, the physicians can make use of 3D printing to make products that particularly match an individual's anatomy.Want To Learn More? Register For E-mails On The Most Recent Information On Additive Manufacturing

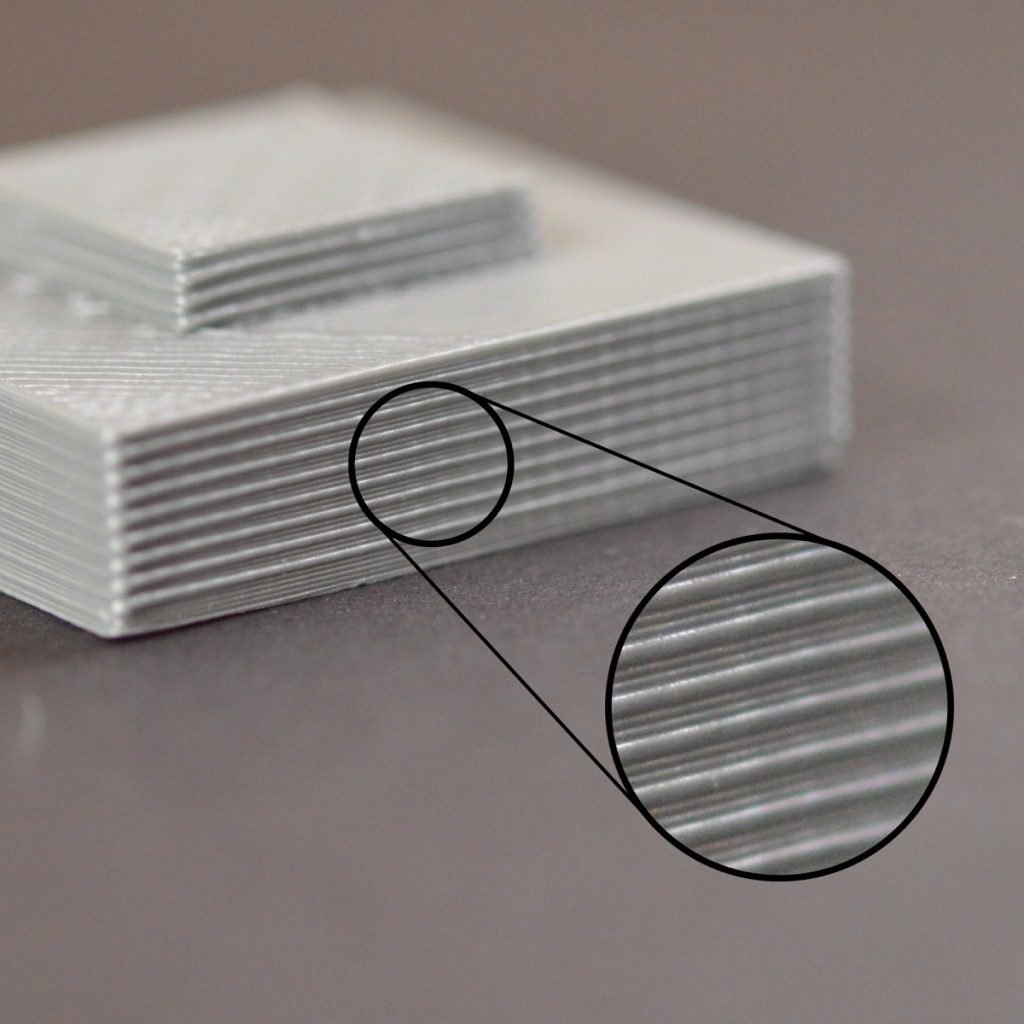

All 3D printing systems rely upon premium, specially created print heads developed for 24/7 operation. 3D printing post-processing is a crucial facet of the 3D printing process, as it boosts the high quality, look, and also mechanical residential or commercial properties of printed components. By recognizing and mastering these methods, you can make sure that your 3D printed components meet industry-specific demands and also achieve the preferred capability and visual appeals.- Post-processing describes the steps and methods related to 3D printed parts after they have actually been created by a 3D printer.

- After the primer has fully treated, the component ought to be gently fined sand making use of fine-grit sandpaper to get rid of any kind of imperfections as well as produce a smooth surface for paint application.

- After that, a jetting head just like one in a 2D printer distributes binding polymer in the form of the part cross section, loosely sticking the powder.

Assistance Elimination

Rough blasting criteria, such as the type of unpleasant media, blowing up stress, and also nozzle range, can be adapted to control the aggression of the process and also the wanted surface area finish. For instance, using great glass beads at reduced stress will lead to a smoother, extra sleek surface area, while crude aluminum oxide bits at higher pressures will certainly create a rougher structure. Water jetting involves using a high-pressure stream of water to blow up away the excess powder or binder material from the component.3D Printing Advanced Technology Center Opens in Japan to Spur ... - All3DP

3D Printing Advanced Technology Center Opens in Japan to Spur ....

Posted: Wed, 26 Apr 2023 07:00:00 GMT [source]

Social Links