November 22, 2023

Printing Ideas Archives Stldenise3d

3d Printing Ideas + Easier Cad As an example, PLA works best under the activity of a strong cooling follower. As a result, you need to decrease the cooling price based on the material you are collaborating with. According to Cura, a preferred slicer, you can strengthen your 3D prints by adjusting the line width to an even numerous of the layer elevation. One more advantage right here is that you can reduce some blemishes on your models depending on what concerns you are having. Issues like ghosting or having blobs/zits on your design can be minimized by lowering your print speed. Take a look at the video clip listed below for a good aesthetic regarding 3D printing at various layer heights. The video listed below is a great aesthetic on how to post-process your 3D prints to a truly high standard. Calibrating your 3D printer is essential for obtaining the most effective quality 3D prints, especially the extruder. Leveling your 3D printer's bed is basic for successful 3D prints. When your bed is unequal, it can lead to printing failures also near completion of a very long print. Some filaments are much more hygroscopic while others are less. You ought to be maintaining your filament dry to make certain that it does optimally as well as does not make your print's surface area texture look bad.Calibrate Retraction Settings

See to it that you publish the material within the supplied array for the best results. Obtaining the best temperature levels in 3D printing is very important for obtaining the most effective top quality and also success rate. When your printing temperature isn't ideal, you may get print blemishes like layer separation or poor surface area quality.- So I discarded the task I was working with and made a decision to o something tiny, but make it function up until I was either effective, or hemorrhaging from my ears.

- You do not require to make use of much as a little of the hardener can layer as well as strengthen the print.

- I have actually been dealing with a large-scale CSS Hunley, printing it on my industrial printer, the Duplicator 5.

- It took about 10 to 15 mins to see any kind of change in any way.

- So in March 2014 I built them their aircraft, based off a picture I had provided for them at the exact same time.

Calibrate Your Nozzle As Well As Bed Temperatures

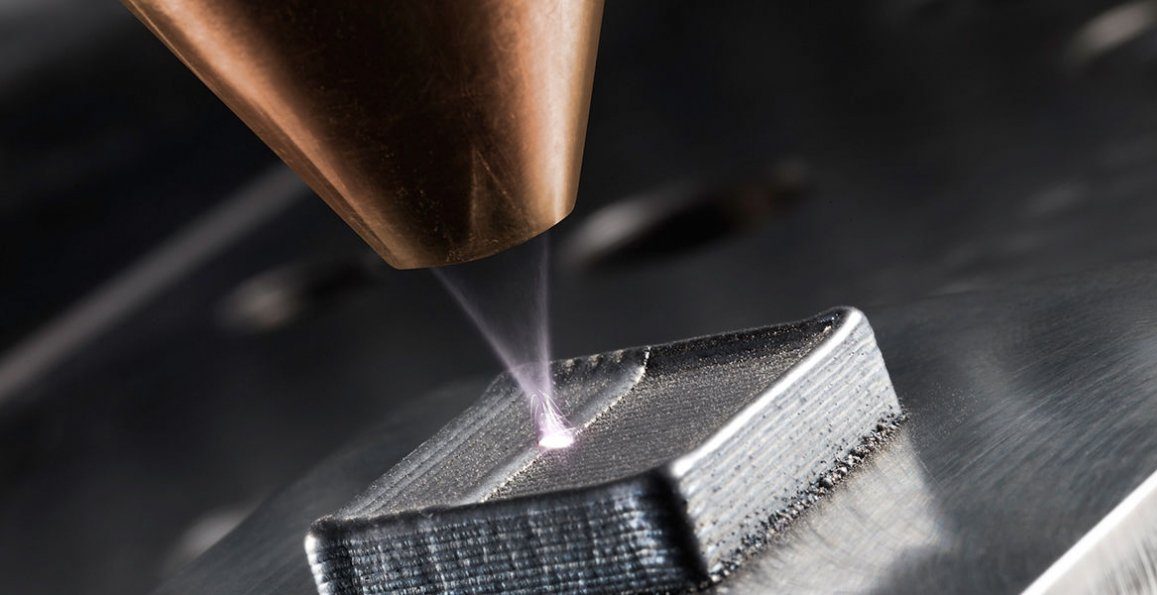

Wall surface thickness goes together with non-manifold geometries, as we saw above, geometries without quantity can't be produced. Walls that are also thin make small parts on the model incapable to be published or really fragile, with a high opportunity of breaking. In order to publish a geometry, it requires to have a quantity, so a shape with "missing out on" surfaces or no volume isn't practical. This would be the matching of asking your 3D printer to publish one straight line and also anticipating it to find out in 3D. A simple way to comprehend manifold geometry is by understanding non-manifold geometry. The very best cost-free slicer is Cura, as well as the most effective paid option is Simplify3D.Expertise in 3D printing — and a little sabotage — reveal new ... - Argonne National Laboratory

Expertise in 3D printing — and a little sabotage — reveal new ....

Posted: Wed, 12 Apr 2023 07:00:00 GMT [source]

Why are my 3D prints so bad?

One of the most usual reason is https://nyc3.digitaloceanspaces.com/custom-printing/Printing-Techniques/graphic-software/44-typical-3d-print-issues-repairing-concerns.html merely that the print just does not bond to the surface area of the print platform. The filament requires a distinctive base in order to adhere, so to address the concern you''ll need to produce a much better bonding surface. An unlevel print system can be one more major issue.

Social Links