November 22, 2023

What Is 3d Printing As Well As What Is Additive Production? Hp ® Main Site

Safe And Secure 3d Publishing The Brand-new Disruptive Modern Technology As Well As Enjoy The Marketplace Expand The bridge has an overall https://nyc3.digitaloceanspaces.com/custom-printing/Printing-Techniques/graphic-software/just-how-to-design-for-3d-printing-optimize-your-3d-versions-for.html length of 12 meters as well as a size of 1.75 meters and is published in micro-reinforced concrete. Building layout was done by Institute of Advanced Architecture of Catalonia. Architect James Bruce Gardiner created two projects, Freefab Tower in 2004 as well as the Rental property Roccia in 2009-- 2010.Dental 3D Printing Market to register a 9% CAGR from 2023 to 2031, expected to accumulate a Valuation of USD 2.9 billion: TMR Report - Yahoo Finance

Dental 3D Printing Market to register a 9% CAGR from 2023 to 2031, expected to accumulate a Valuation of USD 2.9 billion: TMR Report.

Posted: Fri, 09 Jun 2023 17:30:00 GMT [source]

Typical Applications Of 3d Printing

For each task, a research report has actually been issued, as well as the gathered information has actually been made use of to unify all the various technologies into a very first effort at an usual standardized classification as well as terminology. The Chinese company WinSun has actually developed numerous residences making use of huge 3D printers using a mix of quick drying cement as well as recycled basic materials. 10 presentation homes were claimed by Winsun to have actually been built in 24-hour, each costing US$ 5000 (structure not consisting of, footings, services, doors/windows as well as fitout). Nevertheless, building and construction 3D printing leader Dr. Behrokh Khoshnevis declares this was faked and that WinSun stole his intellectual property.- With voxeljet functioning along with us to provide molds and also cores, we will certainly have the ability to compress lead times even further for our consumers, while additionally setting brand-new documents in terms of the size and weight of components we can cast.

- Additionally, the DED procedure is restricted to steels only and works well with both wires as well as powders.

- The brother or sister of Selective Laser Melting, Direct Energy deposition additionally uses a laser and also metal powder to fabricate metal parts.

- A 2nd column is the thorough exposure assessments have actually been performed by the NIOSH Nanotechnology as well as Advanced Products Area Researches Teamat 10 various additive production sites.

Extraterrestrial Printed Frameworks

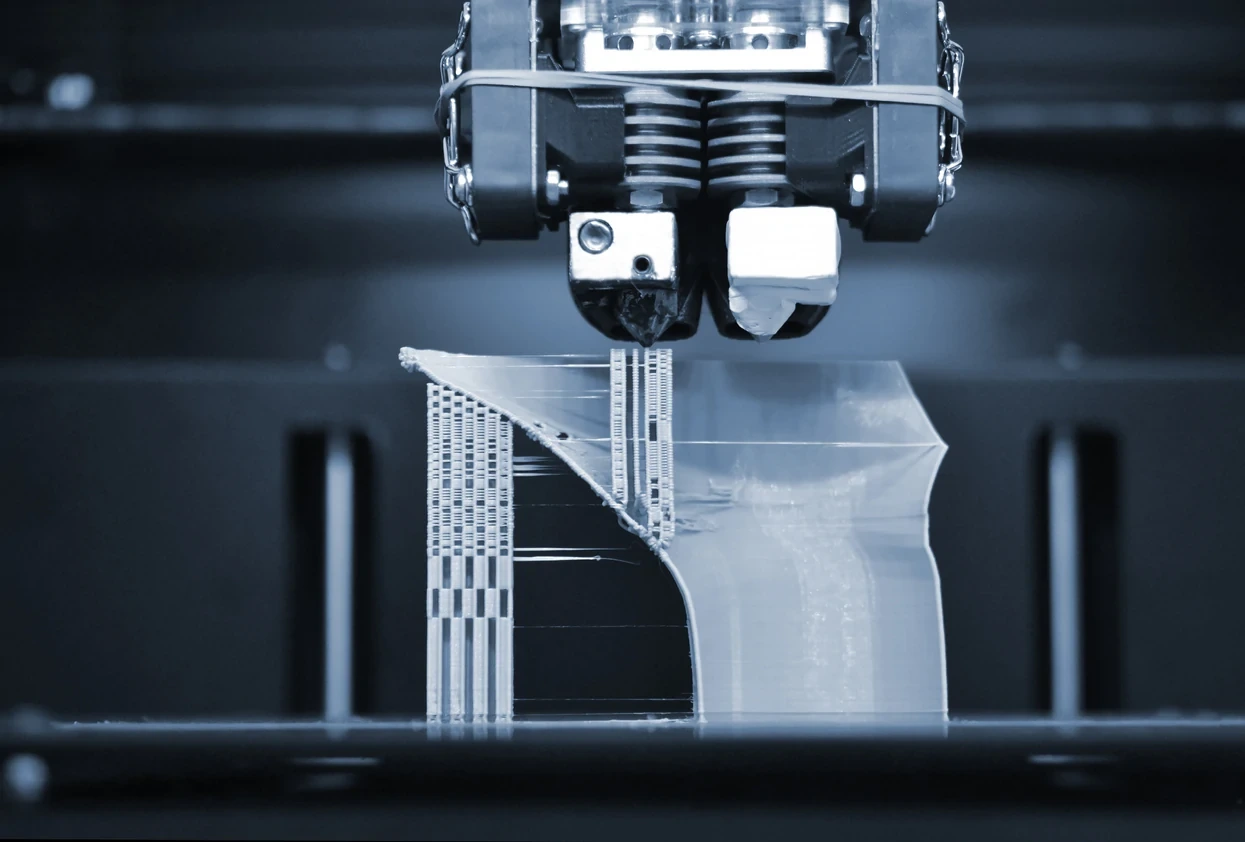

SLS resembles 3DP in binding together powder fragments in thin layers other than a CO2 laser beam of light is used. The laser scans the surface area of the powdered polymer bits in a specific 2D pattern to sinter by warming them over the glass transition temperature. During sintering, molecular diffusion along the outer surface area of the fragment cause neck development in between bordering bits. After one layer is produced, the piston having the component is lowered as well as a fresh layer of powder product is rolled throughout the top surface area. Unbound, loose powder is removed after the component is completed as well as is warm dealt with to accomplish full density. Short-term assistance frameworks are not needed, unlike in SLA, considering that unbound solid fragments support any kind of cantilever structures. If, on the various other hand, you're creating components from scratch, it is important to understand DFM concepts for 3D printing as well as some basic CAD (Computer-Aided Style) skills. Industrial applications are the big-ticket usages, yet there are lots of things you can make with a 3D printer at home as well. Online systems like Thingiverse maintain considerable catalogs of amazing stuff to 3D print. Find out full blast about this functional production modern technology that continues to progress and get brand-new applications. As an example, it is possible to 3D print in biomaterials to create complicated cells versions. And also, on a lighter note, it's also feasible to make use of edible materials, like chocolate. This object is generated by a 3D printer, which "converts" the CAD file right into a 3D design. It typically does this by depositing material layer by layer in exact geometric shapes utilizing a printhead, nozzle, or other printing modern technology. Each layer can be seen as a thinly cut straight cross-section of the ultimate things. FDM has generally used biocompatible polymers with reduced melting temperature levels. In vitro researches have actually been carried out with porcine chondrocytes, mouse pre-osteoblasts, as well as bone marrow-derived mesenchymal stem cell.Which modern technologies are presently made use of in 3D printing?

- Material Extrusion.Fused Deposition

- Modeling( FDM) 3D Bioprinting.Construction 3D Printing.Vat Polymerization.Stereolithography (SLA)

- Digital Light Handling( DLP) Fluid Crystal Present( LCD)

Social Links