Gas vs No Gas: What Wire Works Best with Gas Shielding?

In the world of welding, understanding the nuances of shielding gas and its role in the welding process is crucial for achieving optimal results. The debate of "Gas vs No Gas" is not just a technical discussion; it's about ensuring quality, safety, and durability in the work produced. So, what wire works best with gas shielding? This comprehensive article will delve into every aspect of this topic, providing insights on various welding techniques, materials, and safety considerations.

Understanding Welding and Its Importance

Welding is a fabrication process that joins materials—most commonly metals or thermoplastics—through coalescence. It’s an essential technique used in various industries, from construction to automotive manufacturing.

What is Welding?

Welding involves melting the base material and adding a filler metal to create a strong bond once cooled. It can be performed using different methods, including arc welding, MIG (Metal Inert Gas), TIG (Tungsten Inert Gas), and more.

Classification of Welding Processes

The classification of welding processes can be broadly divided into:

Each method has its unique applications based on the materials being welded.

Gas vs No Gas: What Wire Works Best with Gas Shielding?

When discussing "Gas vs No Gas," it’s vital to understand how shielding gases impact the quality of welds. Shielding gas protects the molten weld pool from atmospheric contamination that could lead to defects.

Welding Wire Types

- Solid Wire: Commonly used with MIG welding, solid wire requires shielding gas to prevent oxidation.

- Flux-Cored Wire: This type can be used without external shielding gas since it contains flux within the core that generates gases during the welding process.

Conclusion: For high-quality welds in clean environments, solid wire with gas shielding is preferred. In contrast, flux-cored wire is often favored for outdoor jobs or situations where wind would disperse shielding gas.

Welding Fumes: Safety Considerations

Given that many people wonder if are welding fumes toxic, it’s essential to address this concern.

Are Welding Fumes Toxic?

Yes, welding fumes can be toxic depending on the materials being welded and exposure levels. Proper ventilation and protective equipment are necessary for safe operation.

Protective Equipment and Safety Gear

When working in environments involving welding:

- Use welding helmets—some models are even solar-powered!

- Ensure your welding gloves are heat resistant.

- Invest in welding blankets that are fireproof.

This gear will help mitigate risks associated with fume inhalation and heat exposure.

Welding Jobs: Demand and Opportunities

The question arises: Are welding jobs in demand?

Industry Needs for Welders

Absolutely! The need for skilled welders continues to grow as infrastructure projects expand globally. Industries such as construction, manufacturing, automotive repair, and shipbuilding offer lucrative opportunities.

What Welding Jobs Pay the Most?

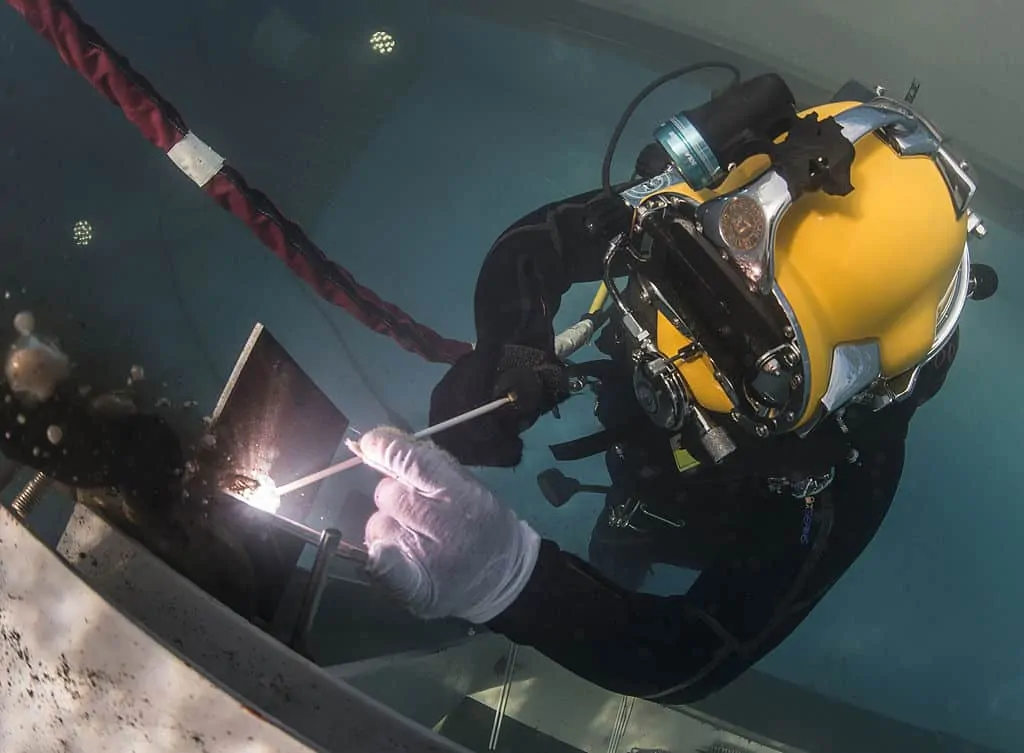

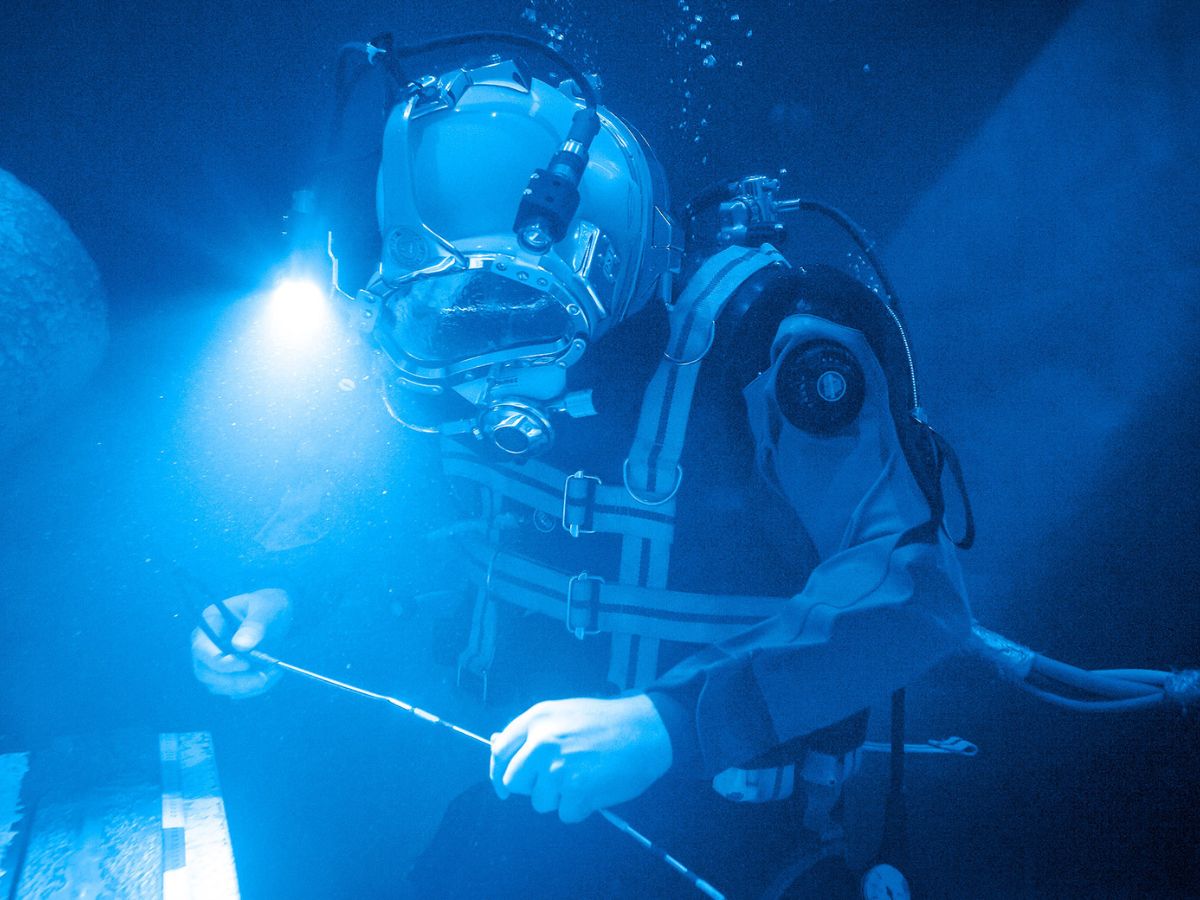

High-demand areas include underwater welding and pipeline welding roles which often provide substantial salaries due to their specialized nature.

The Process of Making Welding Wire

Understanding how welding wire is made offers insight into its properties and effectiveness during use.

How Welding Wire Is Made

Welding wire production typically involves:

This meticulous process ensures reliability under extreme conditions during welding operations.

Choosing the Right Rod or Wire for Your Project

Selecting appropriate rods or wires significantly affects your project outcome.

What Welding Rod To Use?

Different applications require specific rods:

- For stainless steel: Use 308L or 309L rods.

- For mild steel: ER70S-6 is ideal.

Knowing what welding rod for aluminum can also save time—typically ER4047 or ER5356 works best here!

Understanding How Different Gases Affect Welds

When it comes to choosing gas types during MIG or TIG processes:

What Welding Gas For MIG?

Common choices include Argon or a mixture of Argon and Carbon Dioxide for better penetration and bead appearance.

What Welding Gas For Stainless Steel?

Pure Argon is often recommended due to its inert properties which help achieve clean welds without contamination.

How Does Shielding Work During The Process?

Shielding gases protect against oxidation by creating an inert atmosphere around the weld area.

How Does a Welder Hold Their Equipment?

Typically when welding, you should hold your torch at a slight angle to maintain control over your bead placement while allowing proper gas flow around the weld area.

Effects of Welding on Health: Eye Protection Is Key!

With questions like how does welding affect the eyes, it’s crucial to take precautions seriously:

Why Are Specialized Helmets Necessary?

The intense light produced can lead to “arc eye,” causing painful irritation if proper protection isn’t worn!

Are Welding Goggles Safe?

Yes! Quality goggles provide sufficient protection from harmful UV rays emitted during arc processes while allowing clear visibility of your workpiece.

FAQs About Gas vs No Gas in Welding

Here are some frequently asked questions related to our topic:

Are welding sparks dangerous?

Yes! They can ignite flammable materials nearby; always work in a safe environment.

Are welding gloves fireproof?

While they resist heat effectively, no glove is entirely fireproof; avoid prolonged exposure.

How does a welding transformer work?

It converts high voltage electricity into usable lower voltage power suitable for different types of welders.

What shade should I use when welding?

Generally between #10 - #14 depending on amperage; lighter shades for lower currents.

When using DCEP configuration during arc-welding…

Electrons flow from the electrode to the workpiece enhancing penetration depth!

ol3/hr1hr1/##

This article serves as both an educational guide and resourceful reference point for anyone diving deep into the realm of modern-day weldings such as those offered by Phoenix Welding Services—a reliable name known throughout Phoenix!