Introduction:

When it comes to prototyping a new product or design, selecting the right materials is crucial. The prototyping stage allows you to test and refine your ideas before moving on to the final production phase. Choosing the appropriate substance for your project can greatly impact the overall success and functionality of your prototype. In this blog post, we will explore the various factors to consider when selecting prototyping materials and provide valuable insights to help you make an informed decision.

Why Choosing the Right Prototyping Material Matters?

When it comes to prototyping, selecting the right material is crucial for the success of your project. The material you choose can greatly impact the functionality, durability, and overall quality of the prototype. With a wide range of materials available, it’s important to understand their properties and characteristics to make an informed decision. In this article, we will explore different prototyping materials and guide you in choosing the right substance for your project.

1. Plastic

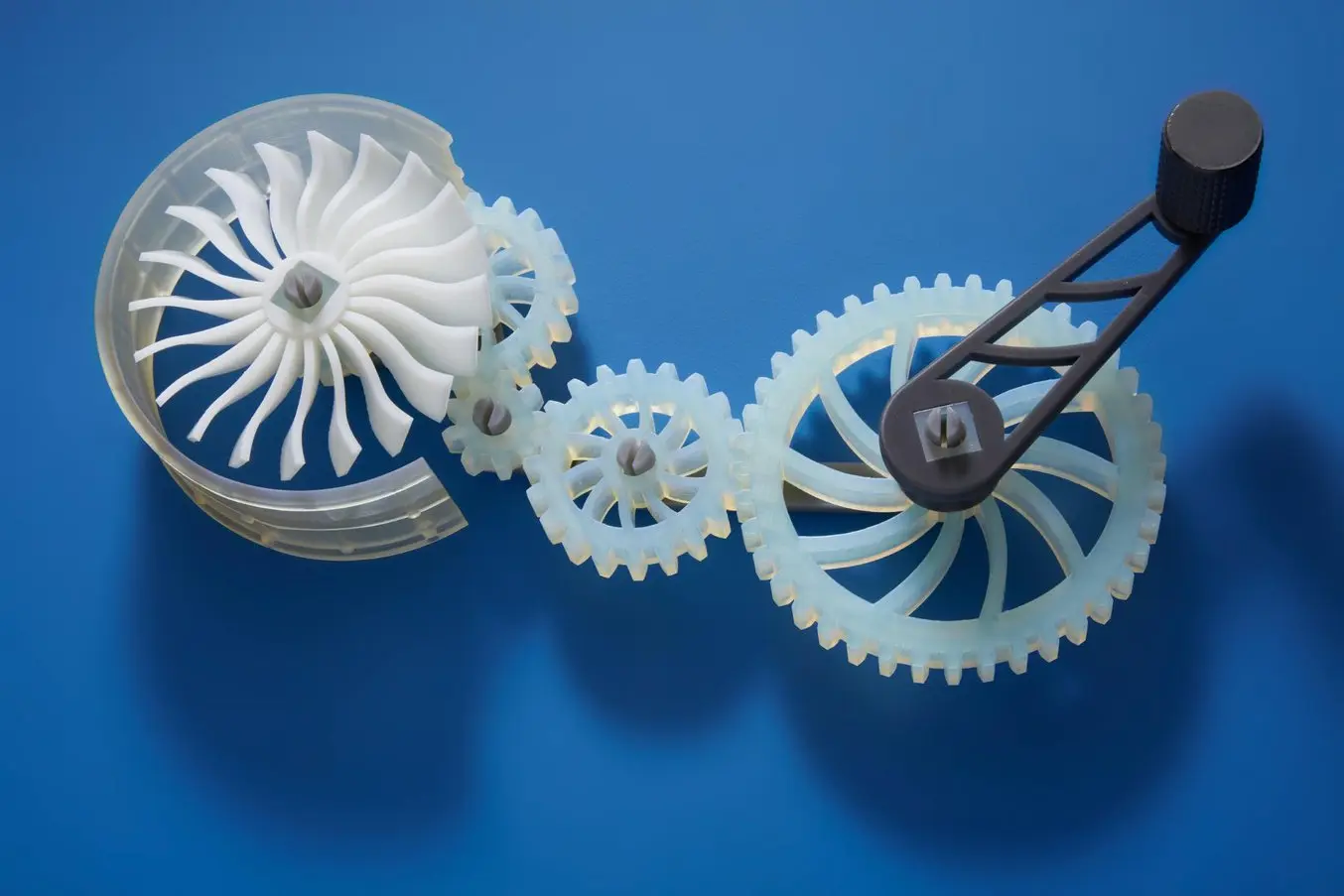

Plastic is one of the most commonly used materials for prototyping due to its versatility, cost-effectiveness, and ease of use. There are various types of plastic materials available, such as ABS, polycarbonate, and polypropylene. Each type has its own strengths and weaknesses, so it’s essential to consider the specific requirements of your project.

Advantages of Plastic Prototyping:

- Wide range of material options

- Easy to machine and shape

- Cost-effective for low-volume production

Disadvantages of Plastic Prototyping:

- May not offer the same strength and durability as other materials

- Limited heat resistance

- May require additional finishing processes for desired aesthetics

2. Metal

Metal prototyping is ideal for projects that require high strength, durability, and heat resistance. Common metals used for prototyping include aluminum, steel, and brass. Metal prototypes are often used in industries such as automotive, aerospace, and robotics.

Advantages of Metal Prototyping:

- Excellent strength and durability

- High heat resistance

- Precise and accurate prototypes

Disadvantages of Metal Prototyping:

- Higher cost compared to other materials

- Requires specialized equipment and expertise

- Longer lead times for production

3. Wood

Wood prototyping is commonly used for projects that require a natural and aesthetically pleasing appearance. It offers a unique and warm feel, making it suitable for products such as furniture, packaging, and consumer goods.

Advantages of Wood Prototyping:

- Natural and attractive appearance

- Easy to work with using standard woodworking tools

- Cost-effective for certain projects

Disadvantages of Wood Prototyping:

- Not suitable for projects requiring high strength or durability

- May require additional finishing processes for desired aesthetics

- Can be affected by moisture and temperature changes

4. Silicone

Silicone is a versatile material often used in prototyping for its flexibility and ability to replicate complex shapes and textures. It is commonly used for creating molds, gaskets, and medical devices.

Advantages of Silicone Prototyping:

- Flexible and durable

- Excellent for creating molds and reproducing complex shapes

- Can withstand high and low temperatures

Disadvantages of Silicone Prototyping:

- Higher cost compared to other materials

- May require specialized equipment and expertise for molding

- Longer production time for complex designs

Summary:

Prototyping materials play a significant role in the development of any product or design. They allow you to create functional replicas of your intended end-product, enabling testing, refinement, and iteration. The selection of the right substance for your prototype is crucial, as it can impact the final product’s durability, performance, and aesthetics. This blog post will guide you through essential factors to consider when choosing prototyping materials, such as mechanical properties, cost, availability, and manufacturing techniques. By understanding these considerations, you can make informed decisions and optimize your prototypin click to read g process for successful outcomes.

Q: What factors should I consider when choosing a prototyping material?

A: When choosing a prototyping material, consider factors such as the desired physical properties, cost, availability, manufacturing process compatibility, and the intended use of the prototype.

Q: What are some common prototyping materials?

A: Common prototyping materials include plastic polymers (such as ABS, PLA, and nylon), metals (such as aluminum and steel), wood, foam, and various types of resins.

Q: What are the advantages of using plastic polymers for prototyping?

A: Plastic polymers offer advantages such as versatility, low cost, lightweight nature, ease of manufacturing, and compatibility with 3D printing technologies.

Q: How do I choose the right metal for my prototyping project?

A: The choice of metal for prototyping depends on factors such as desired strength, corrosion resistance, machinability, and cost. Consider materials like aluminum for lightweight applications, stainless steel for corrosion resistance, and steel for durability.

Q: When should I consider wood as a prototyping material?

A: Wood is a suitable choice when aesthetics, intricate detailing, or structural stability are important for the prototype. It is commonly used for architectural models, furniture prototypes, and consumer product designs.

Q: What are the advantages of using foam for prototyping?

A: Foam materials such as expanded polystyrene (EPS) or polyurethane foam offer advantages like lightweight construction, ease of shaping, low cost, and good insulation properties. They are commonly used for packaging prototypes, automotive designs, and architectural models.

Q: How do I choose the right resin for my prototyping project?

A: The choice of resin depends on factors such as desired transparency, hardness, flexibility, and chemical resistance. Consider materials like epoxy resin for high strength, polyurethane resin for flexibility, or clear acrylic resin for transparent prototypes.