Dayton Band Saws

Table

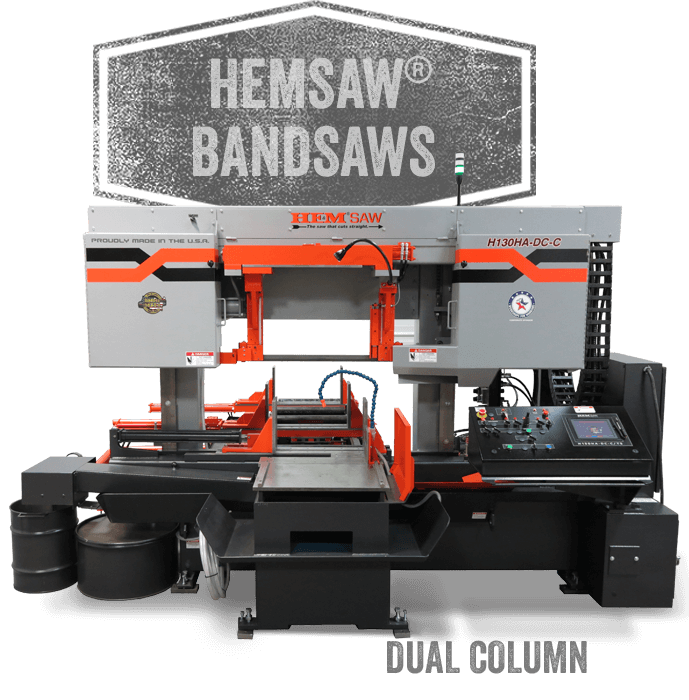

The pressure from the wheels caused the blades most often to burst because of how the blade loops bend and flex around them.

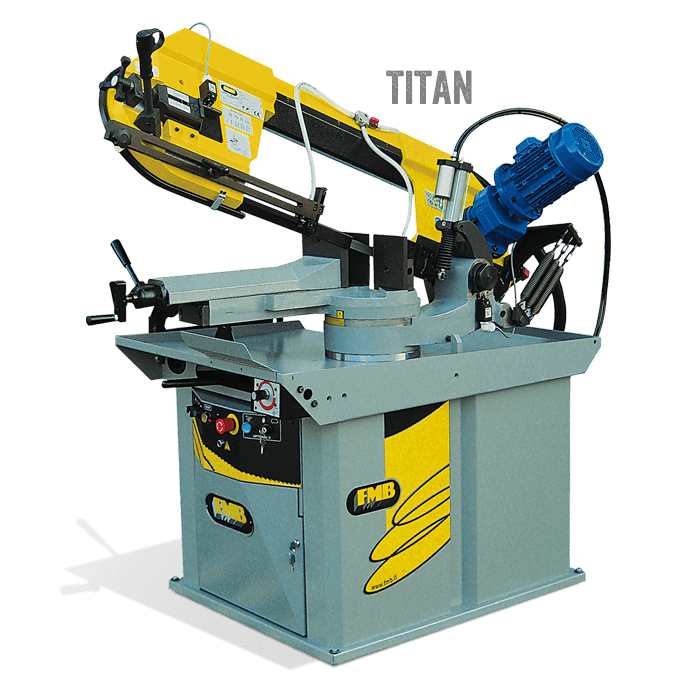

This heavy piece of equipment weighs in at 247lbs. This equipment is capable of absorbing a lot pressure.