Accessories

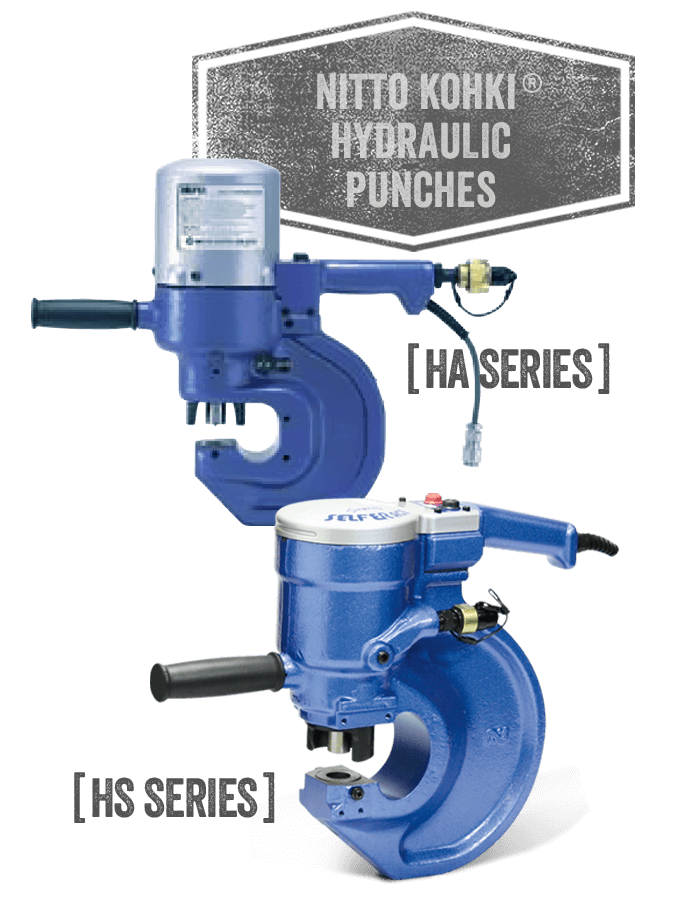

You have come to the right spot if you are looking for a portable, single-acting hydraulic punch that is both accurate and practical. We offer a variety of punches suitable for your needs. Please feel free to contact us with any suggestions or requests. We are always available to answer your technical queries.

The 35-Ton hydraulic punching machine weighs 31 pounds and punches quickly. The dual-action remover holds the material and strips it so that you can punch the next hole in just seconds. It is suitable for punching railings, I-beams, tower iron, truck frames and truck frames. The maximum tensile strength is 65,000 Psi. Mount it to your work bench, or bring it to your job site. In less than 24 hours, rectangular, square or hex tools can be ordered.