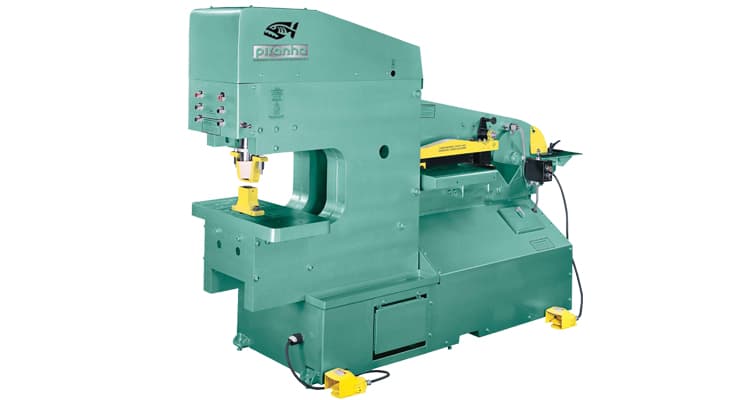

Piranha Iron Worker Machines California

Piranha Single Operator ironworkers can handle most tasks. But, if two simultaneous operations are required (e.g. Dual operator ironworkers are your best bet if you have to do both punching or notching.

Whitney Single End Punch Presses (Piranha and Whitney) are making it easier to punch larger sheets, have deeper throats, or require more punching ability.