Tooling

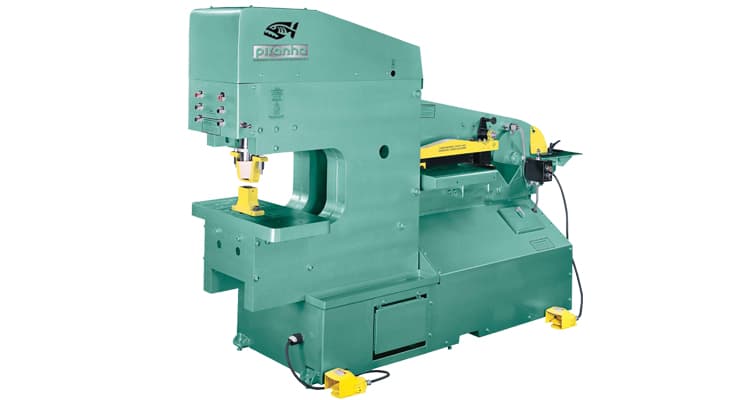

Metal fabricators can rely on Piranha ironworkers for their exceptional quality and innovative features. Each Piranha ironworker provides high quality work, cost savings, flexibility, and adaptability through a wide variety of tools and factory engineering support.

The single operator ironworker from Piranha can do most of the tasks that you request. If two simultaneous operations (e.g. A dual operator ironworker is your best choice if you need to punch and notch simultaneously.