How do you build a hydraulic punch

The mold can be adjusted to accommodate a wide range of holes and different shapes.

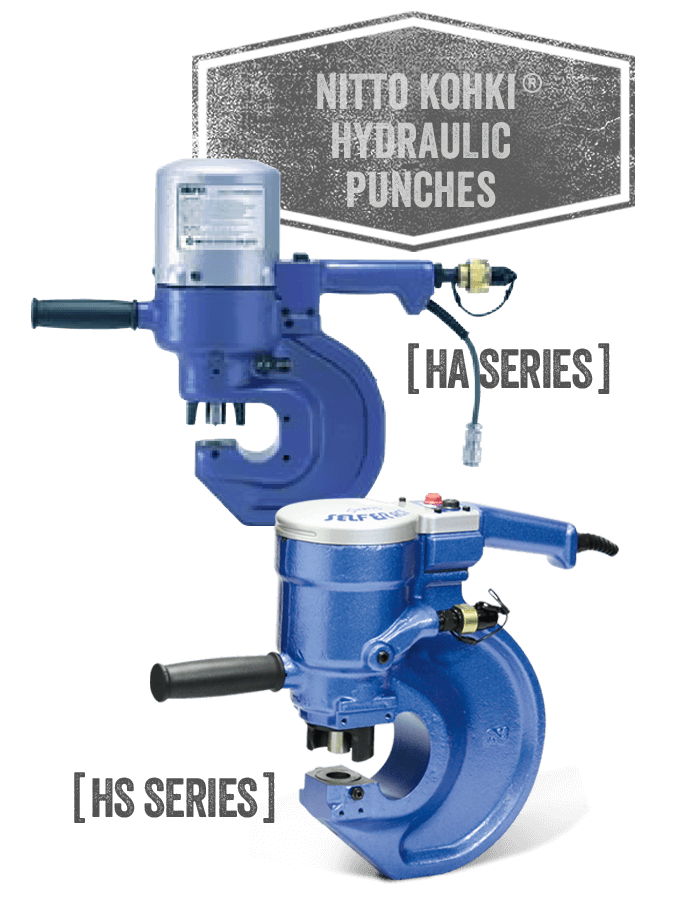

The portable, double-acting hydraulic punches can handle a wide variety unique shapes, regular, oblong punches and dies.

The single-acting, portable hydraulic punches are great for punching precise and smooth holes in a short time. They are also faster than drilling and can be used to drill more accurately. It can punch holes in various materials like angle steel, channel steel and H-shapes.

GSS Mchinery's portable, double-acting hydraulic punches are ideal for fast production of holes and slots in various materials like beam flanges and angle channels, plates and bar stock.

Our portable single-acting hydraulic punches are vastly used in the electricity industry, construction, and various outdoor fieldwork. It allows a maximum punching thickness of about 16mm, a maximum punching diameter of 24mm, and a maximum throat depth of 110mm.

Simply adjust the mold to process a variety of holes of different shapes and specifications.

The mold can be adjusted to accommodate a wide range of holes and different shapes.

The portable, double-acting hydraulic punches can handle a wide variety unique shapes, regular, oblong punches and dies.

A great steel welded machine construction provides excellent temperature relief, rigidity, precision, durability, and strength. Both manual and electrical hydraulic pumps are available.

GSS Machinery Portable Hydraulic Punches provide a quick and efficient way to produce holes and slots in beams, angle, channels, plates, and bar stock. This steel hole punch has a Double Action design which reduces cycle times. It is also portable and easy to use, which results in high-efficiency hole production.

Numerous industries use hydraulic punches. They can save time, provide excellent cycle times and are easy to use.

Our range of portable double-acting hydraulic punches boasts a 27mm diameter capacity, a maximum thickness of 13mm in steel, and a 60mm maximum throat depth.

Portable single-acting hydraulic punches are ideal for punching smooth and accurate holes in a short period, making them remarkably faster and better than drilling. It features an automatic punch, returns, and reset operations, making it ideal for various materials such as angle steel, channel steel, H-shapes, and flat sheet(copper plate, aluminum, iron, and steel plate).

The excellent coherence among mechanized workpiece/products is impressive, and the product's safety is enhanced.

This hydraulic punch range has been used in many industries, including utility pole cross arms, electric tower cross arms and elevator brackets.

GSS Machinery provides hydraulic punches which are perfect for punching, forming and other tasks. We are the top distributor of highly efficient hydraulic punches. These punches are well-powered with the finest engines for precise, smooth punches within a short time.

A hole punch, also known as a hole puncher or paper puncher, is an office tool used to create holes in sheets of paper, typically for the purpose of storing the sheets in a binder or folder.

Hydraulic punches are used to create round, square, or oblong holes in metal. They are intended for use with mild steel, nonferrous metals, and some plastics (non-shattering). Hydraulic punches can be powered by hand pumps, air/hydraulic, gas, or electric pumps capable of producing up to 10,000 psi (700 bar).

CNC punching

These machines are typically outfitted with a linear die carrier (tool carrier) and quick change tools. Today, the method is used in situations where laser applications are inefficient or technically impractical. CNC stands for Computer Numerically Controlled.