How do you use the Milwaukee 10 ton knockout tool

Our Porta-Punch Package includes the 35 Ton C-Frame, Electric/Hydraulic Pump, 10' or 20' Hose and four sets of stock Punches and Dies. Choose from 1/4", 5/16", 3/8", 7/16", 1/2", 17/32", 9/16", 5/8", 11/16", 3/4", 25/32", 13/16" punch sizes.

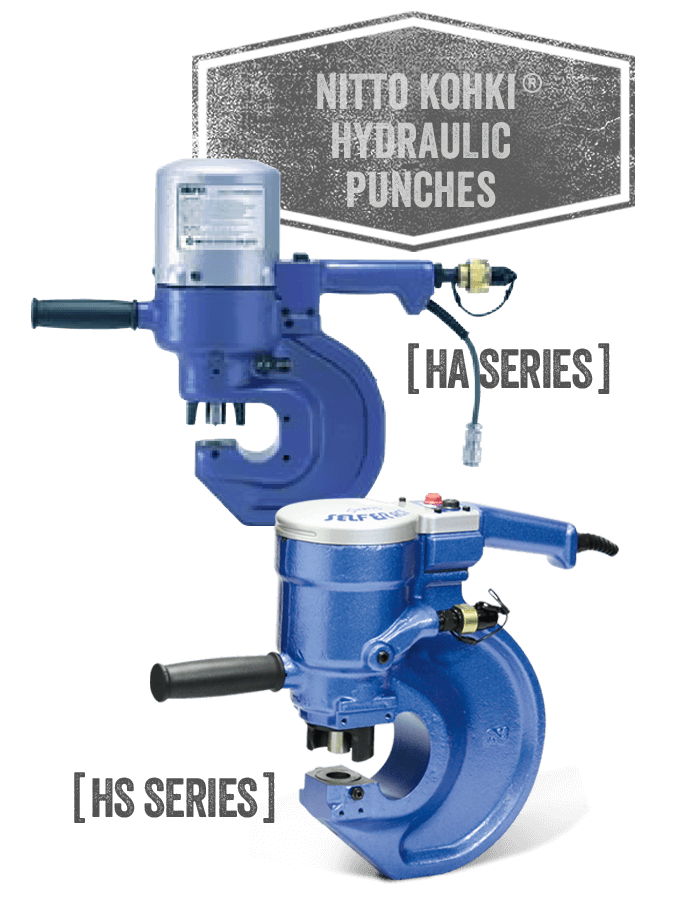

Gulf States Saw & Machine Co. sells portable, double-acting hydraulic punches. They provide a complete automated process of punching and reverting through their inbuilt dexterous control device.