Precision Fabricating Machinery Katy Tx

Combining engineering and technical expertise, GSS Machinery builds custom machinery prototypes, pilot plants and full production lines.

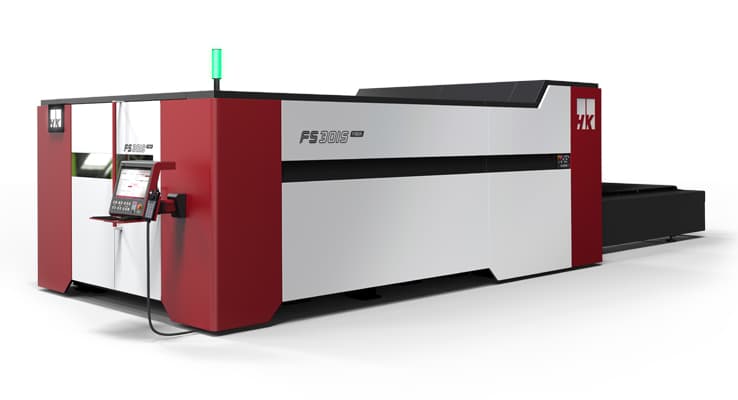

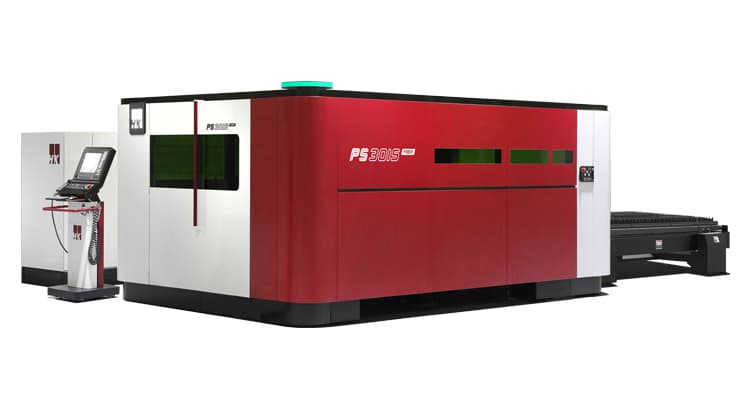

Automating precise metal fabrication requires computer-aided design software, which Tube Lasers utilizes. The intelligent system manages the cutting of your metals to meet the goal of precise fabrication.