Solutions

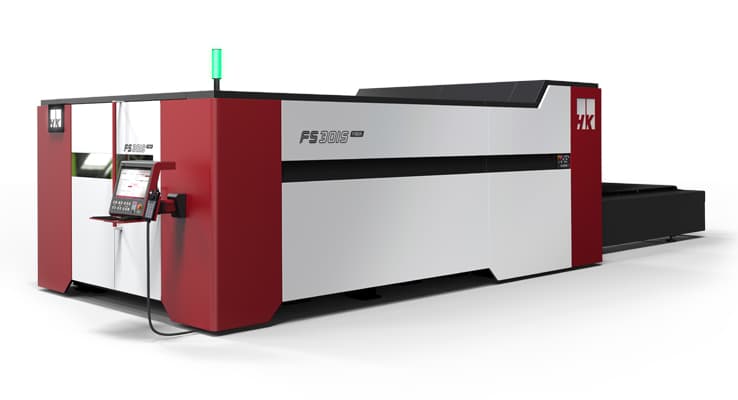

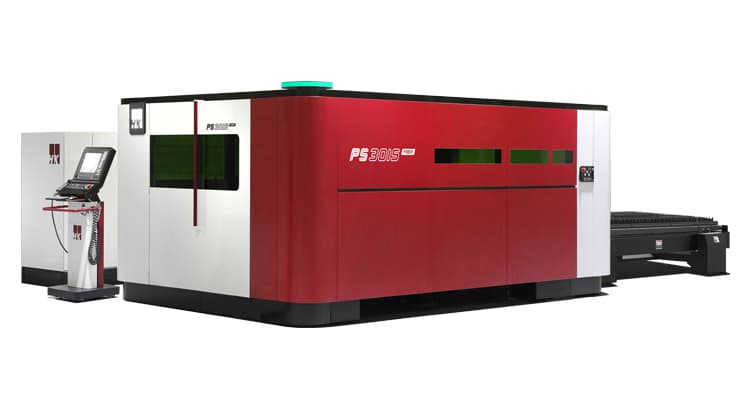

With our Fiber laser systems, you don't need to worry about back-reflected light damaging your laser cutter. These fiber laser machines can be operated more efficiently and require less maintenance.

GSS Machinery is a trusted supplier of custom-made systems and offers vacuum chamber construction for many industrial applications.