Introduction

Offset printing is a widely used printing technique that produces high-quality prints with vibrant colors and sharp details. However, like any printing method, it is not without its challenges. In this blog post, we will discuss some common offset printing problems that can arise during the printing process and provide useful tips on how to avoid them. By being aware of these issues and implementing preventive measures, you can ensure smooth and successful offset printing projects.

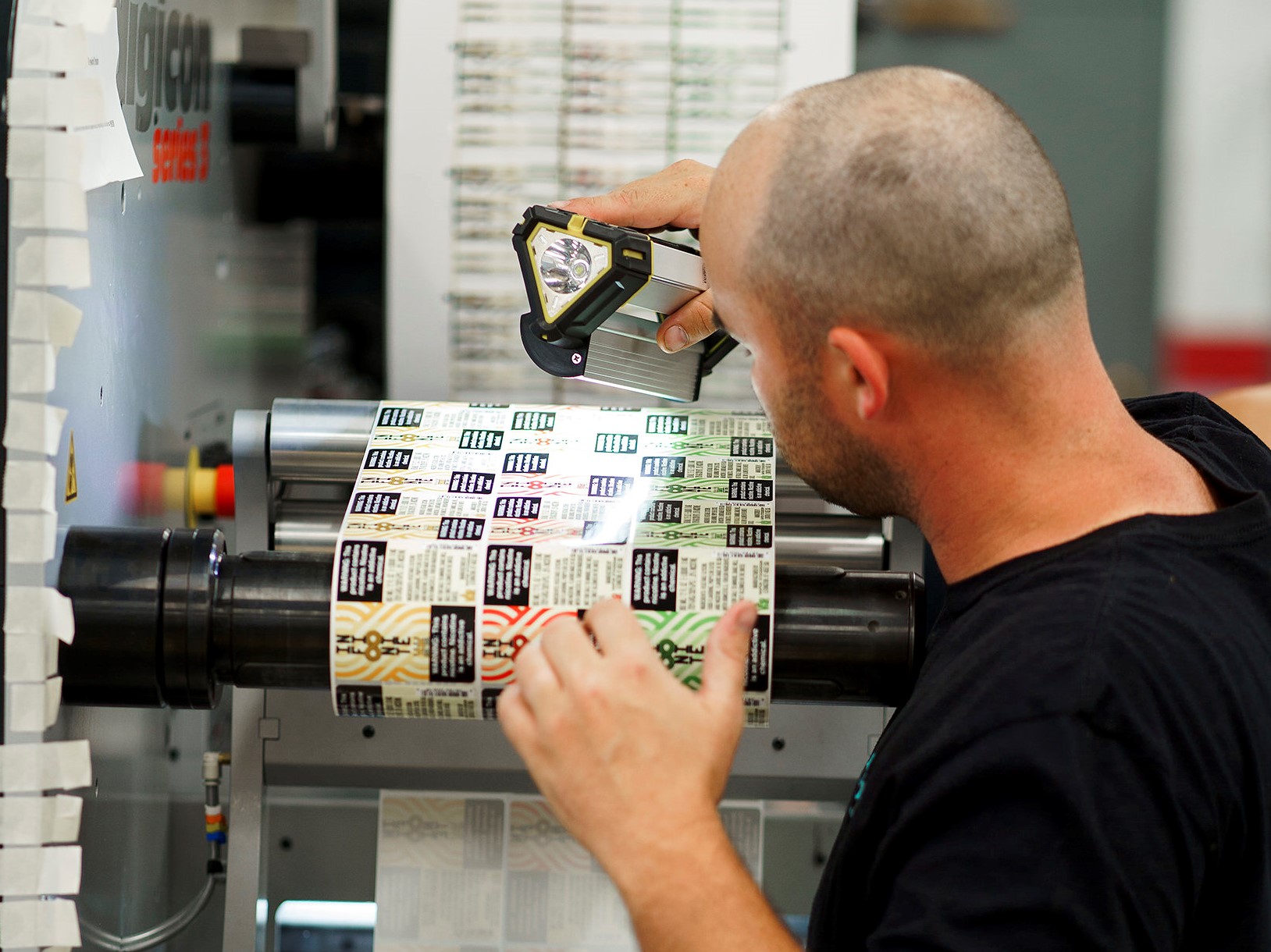

1. Poor Image Quality

One of the most common problems in offset printing is poor image quality. This can occur due to various factors, including low-resolution images, incorrect color settings, or inadequate image preparation. To avoid this problem, ensure that your images have a high resolution, use the correct color profiles, and properly prepare your images before sending them for printing.

2. Color Inconsistency

Color inconsistency is another common issue in offset printing. This can happen when the colors in the final print do not match the colors in the original design. To prevent color inconsistency, make sure to use a calibrated color system, communicate your color preferences clearly to the printer, and request color proofs before proceeding with the full print run.

3. Ink Smudging

Ink smudging can ruin the appearance of printed materials. This problem often occurs when the ink is not allowed enough time to dry properly or when the paper used is not suitable for the printing process. To minimize ink smudging, use the appropriate paper for offset printing, ensure sufficient drying time, and consider using protective coatings or finishes.

4. Misregistration

Misregistration refers to misalignment of colors or elements in the printed material. This can result in blurry or distorted images and text. To avoid misregistration, ensure that the printing plates are properly aligned, use high-quality printing equipment, and regularly maintain and calibrate the printing press.

5. Paper Jams

Paper jams can disrupt the printing process and cause delays. They often occur when the paper used is not compatible with the printing equipment or when the printer settings are incorrect. To prevent paper jams, use the recommended paper type and weight for your printing job, ensure the paper is properly loaded into the printer, and regularly clean and maintain the printer.

6. Plate Issues

Issues with printing plates can lead to various problems in offset printing. These issues may include scratches, dents, or improper plate alignment. To avoid plate issues, handle the plates with care, regularly inspect them for any damage, and ensure they are properly installed and aligned on the printing press.

7. Ghosting

Ghosting refers to faint or unwanted images appearing in areas where they shouldn’t be. This can occur due to improper drying of the ink, ink transfer from previous prints, or issues with the printing plates. To prevent ghosting, ensure proper drying time for the ink, clean the printing press thoroughly between jobs, and maintain the printing plates properly.

8. Paper Curling

Paper curling can make printed materials look unprofessional and can cause difficulties in finishing processes such as cutting or folding. This problem often occurs when the paper is exposed to extreme temperature or humidity conditions. To avoid paper curling, store the paper in a controlled environment, avoid exposing it to extreme conditions, and consider using paper with anti-curl properties.

9. Overinking

Overinking happens when too much ink is applied to the printing plate, resulting in smudged or blurred prints. This can occur due to incorrect ink settings or improper adjustment of ink levels. To prevent overinking, ensure that the ink settings are properly calibrated, regularly check and adjust the ink levels, and conduct regular quality checks during the printing process.

10. Poor Registration

Poor registration refers to misalignment of different print elements, such as images, text, or colors. This can make the final print appear messy or unprofessional. To avoid poor registration, ensure accurate placement of

Summary

Offset printing can encounter various problems that may affect the final print quality and result in additional costs and delays. It is crucial to address and prevent these issues to achieve the desired outcome. In this blog post, we will cover common problems like color inconsistency, image misalignment, and paper jams. Additionally, we will provide practical tips and solutions for avoiding these problems, such as conducting thorough prepress checks, calibrating color profiles, and properly maintaining the printing press. By following these guidelines, you can minimize the occurrence of offset printing problems and optimize the overall printing process.