Manual Band Saws At Lowes

Manual Band Saw 6 Inch Tires

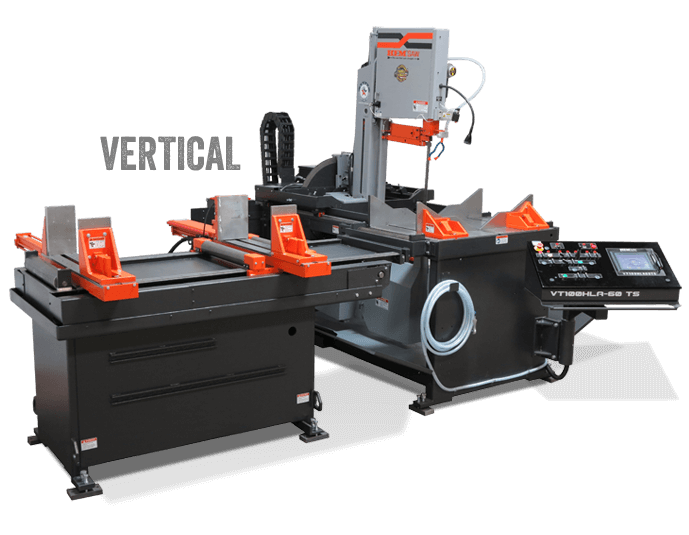

The Rikon 10-324TG 14 in. is the highest vertical capacity floor-standing saw. Band Saw excels in the stand-mounted, more cost-effective category.

It's light-weight and easy to move about the shop. We recommend this benchtop model for beginners. It's very affordable and the adjustments can be made quickly.