Manual Band Saws Class

Iter

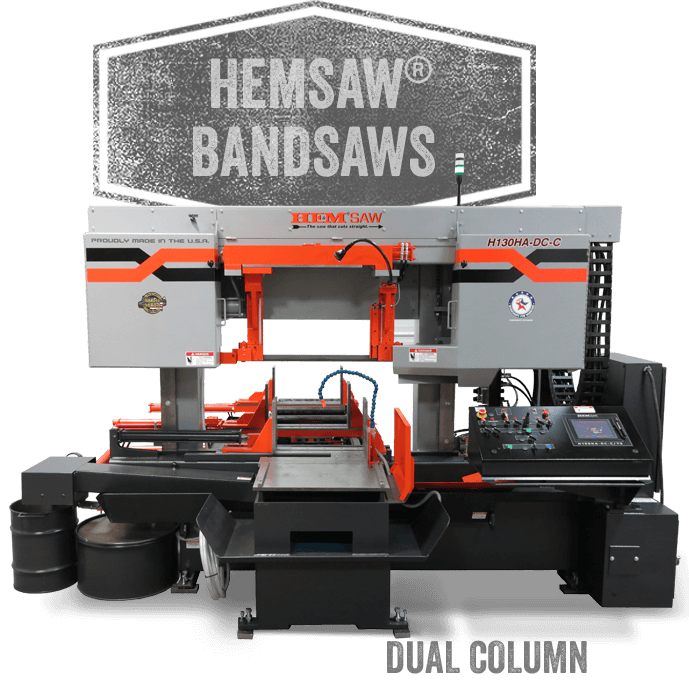

This equipment is 247 lbs. It can withstand high pressure.

There arenít two different machines to cut metal or wood. The same saw can be used for both wood and metal cutting. It is only the blade that's different.

Manual Band Saws Class