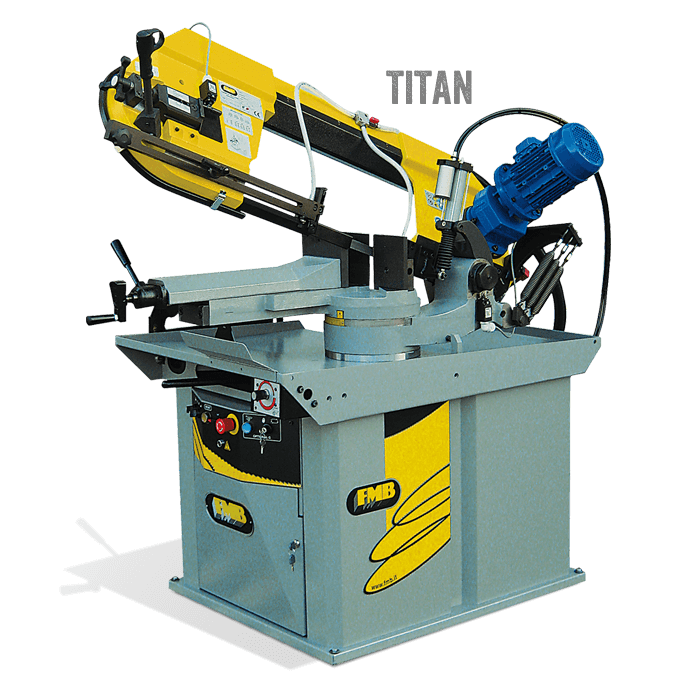

Manual Band Saws Jobs

Pruner

Our circular saws offer precision, quality and value in cutting aluminum and bar stock. The aluminum uncut saw can be set up with semi-auto or auto feed systems. It cuts aluminum without raising burrs. Our CNC Cold Saws are the right choice if you require a saw that can feed multiple CNC machining centers or a forge. This option is a great investment because it can replace up to 4 production bandsaws with one machine.

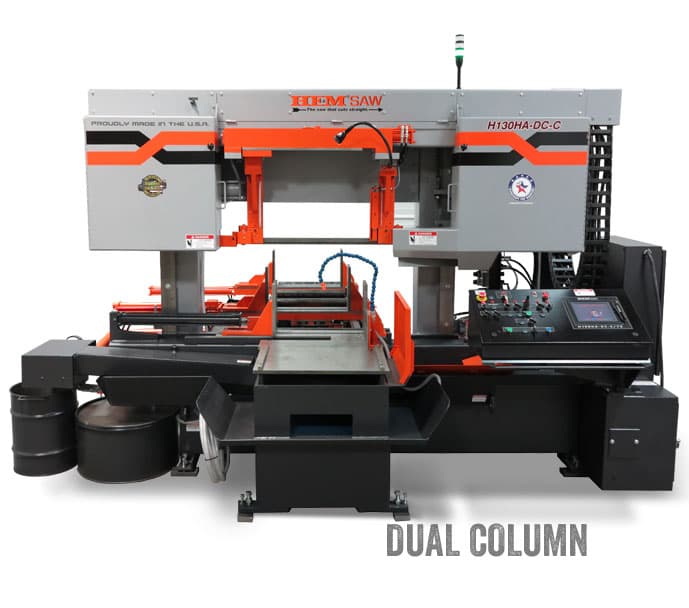

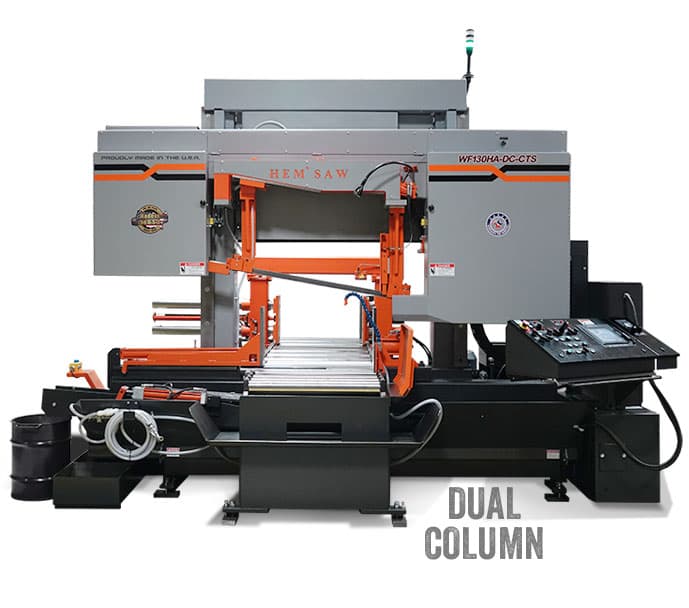

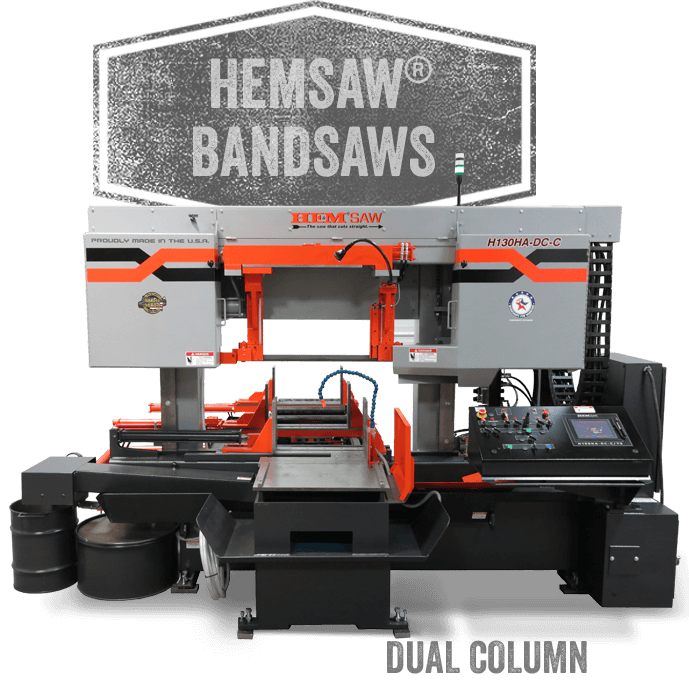

Band saws have a large cutting capacity, which makes it easy to line up different pieces in a row.