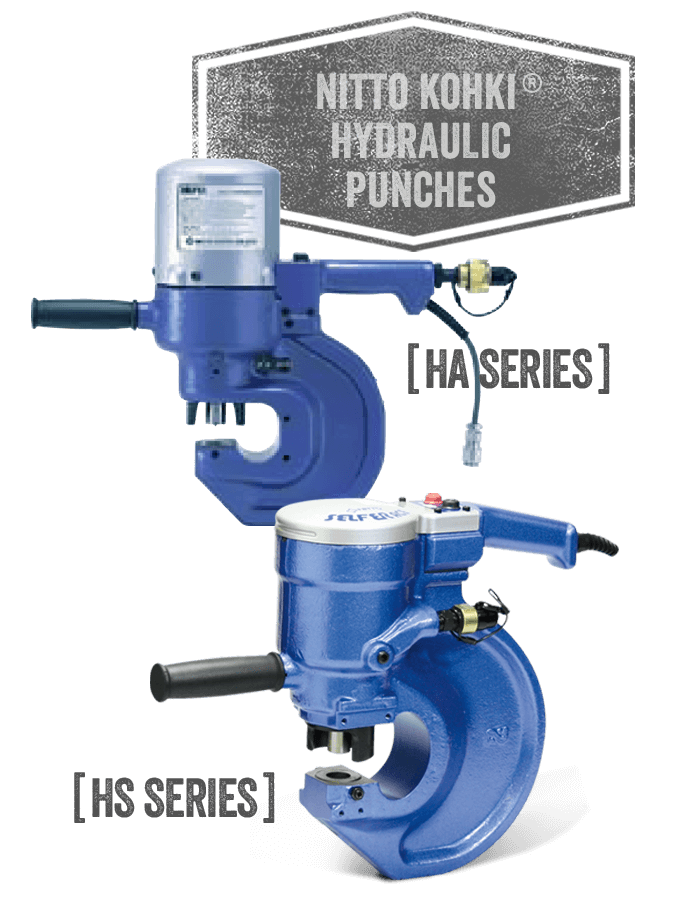

Manual Hydraulic

GSS Mchinery offers a range of double-acting hydraulic punches that can be used to quickly produce holes in various materials, such as angle, channel, beam flanges, bars stock, plates, and channels.

This portable hydraulic punching unit, which weighs in at just 31 pounds, punches in a matter of seconds and is lightweight at only 31 pounds. The dual-action stripper holds and removes material as you punch. It can punch bus bars, tower iron and railings with a maximum tensile force of 65,000 psi. Mount it on your bench or transport it to the jobsite. In 24 hours, rectangular, square and hex tools will be available.