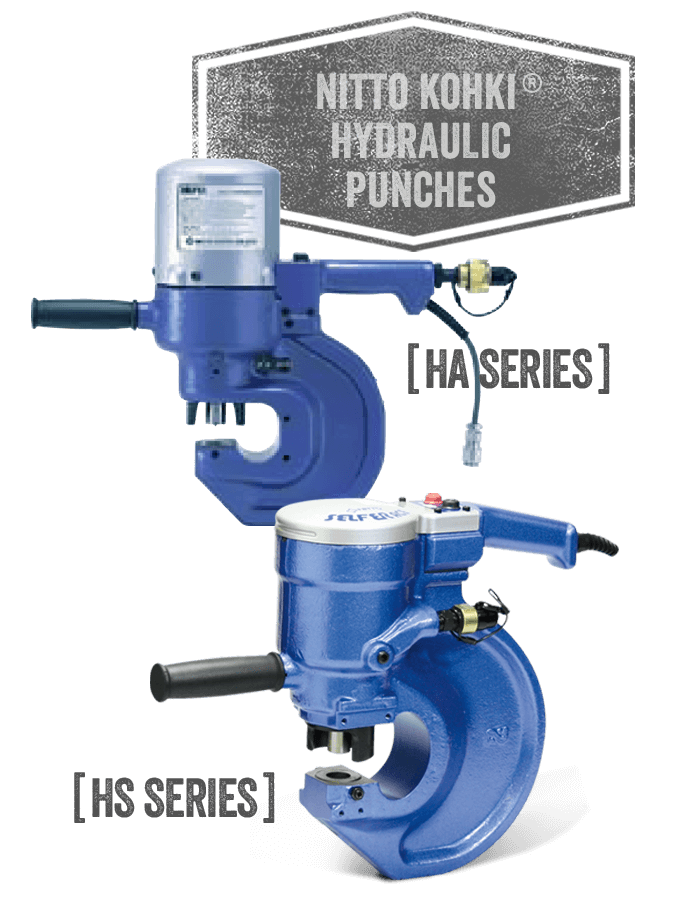

Single Acting Hydraulic Punches In Boxing

It's more effective than traditional hand drills, saves time, is easy to use, and provides high accuracy.

This 14-piece hydraulic kit makes it simple to punch holes into 11 gauge mild or 16 gauge stainless steel. This compact design makes it easy and convenient to carry the hydraulic punch on any job site. This punches are quicker, easier, faster and more precise then manual punches.