Innovative Features

When a variety of machines are used to make complex and thick parts, it can be time-consuming. Piranha Whitney Punch Plasma Combination machines are a popular choice for fabricators. It produces three times as many parts per hour at a third the price.

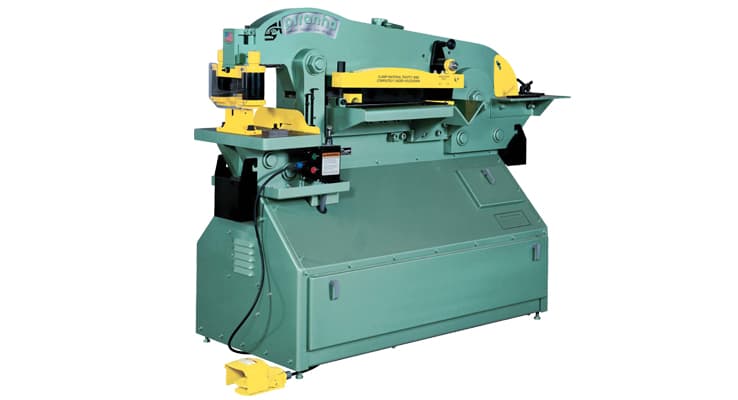

The Piranha Ironworker is a robust ironworker at a great price. Piranha's standard features including a low rake angle ncher and clear view in the work zone allow for precise notching and coping. All Ironworkers include an electronic stroke controller and copper and notchers integrated. Each model has other features.