What is it like being an ironworker

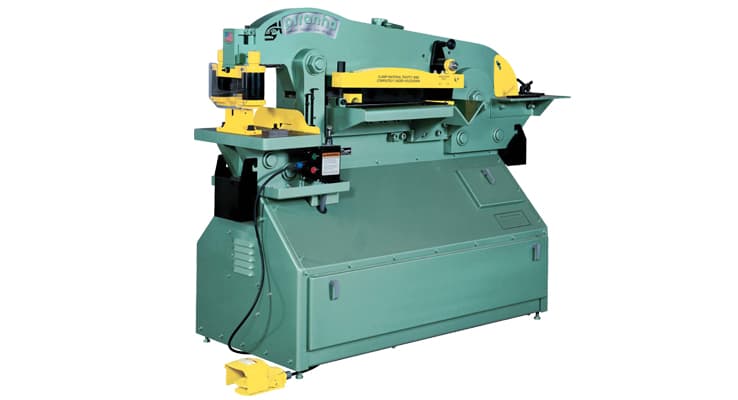

Steel fabricators can switch easily from punching to bend with the P-90 Piranha Ironworker dovetail slider. The Quick-Change Tooling by Piranha has been a hit with metalworking machine shops all over the world. The urethane strippers virtually eliminate part distortion and reduce stroke length. Piranha Ironworker machines are a leader in the market because they have these standard features and more horsepower per ton.

Piranha ironworker machine ranges from 50 to 150 tons and offers metal fabricators excellent quality and innovative features. Every Piranha machine is capable of producing quality work, reducing setup time, versatility, and providing support and engineering in the factory. A single operator Ironworker machine by Piranha is capable of performing almost all applications. Two simultaneous operations, such as punching and notching, can be performed by a single operator ironworker machine. The dual operator ironworker machines are ideal for punching or notching.