Press Brake

You can be sure to deliver high quality and higher profits with our metal fabrication machinery. Piranha solutions include fiber lasers, punch-plasma combination machines and plasma cutting machines. We also offer heavy-duty hydraulic bend rolls, press brakes, plasma table, and a wide range of machine tooling.

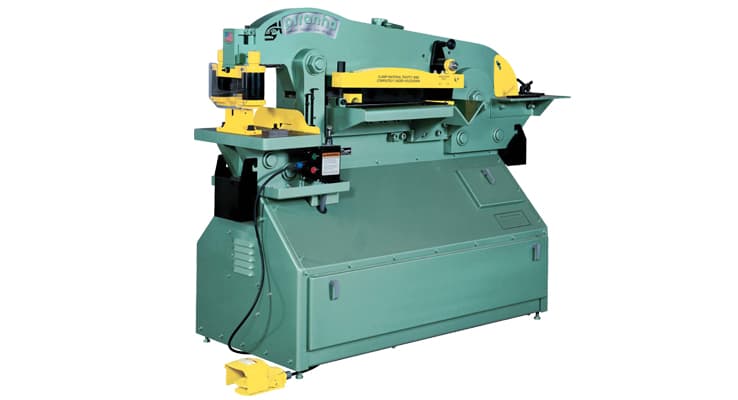

The innovative features and quality of Piranha Ironworkers are a great benefit to metal fabricators. Every Piranha offers quality work, savings on set-up time and versatility through a wide array of tooling and factory engineering.