Piranha

Whitney Single End Punch Presses and Piranha are opening the door to applications that require higher punching capabilities, larger sheets, or deeper throats.

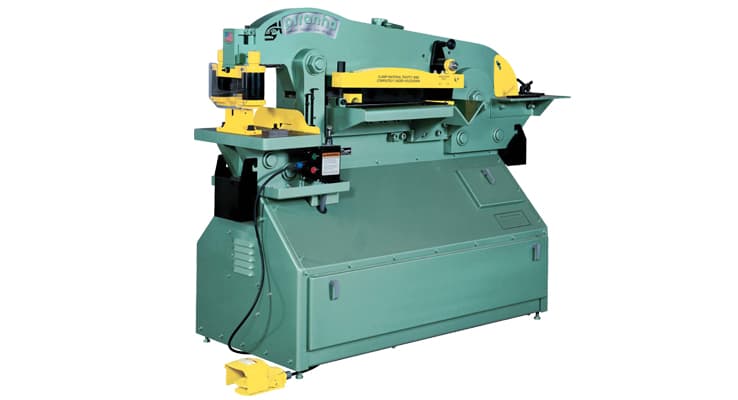

Piranha makes a variety of cutting and forming tools for the metal plate industry. Piranha Whitney is a leader in plate tech and its products serve the global transport, agricultural, construction and equipment industries.