Barcode

Lasertube makes it easy to customize parts according to the requirements of your customers.

We can complete your project in one facility with no downtime and extended lead times. We offer full-service center support that can:

Systems

Fiber lasers can cut thin materials at high speeds. They are also very energy-efficient and require little maintenance. This laser cutting technology has special properties that allow for applications in steel, stainless steel, aluminum, as well as non-ferrous metals like copper and brass.

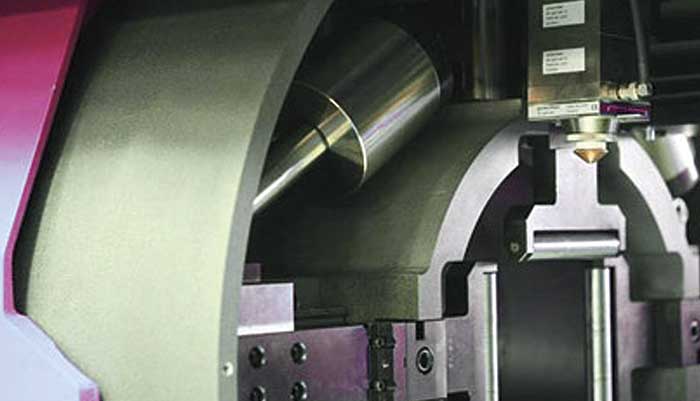

Micrometric Ltd uses a versatile Coherent StarCuttube laser cutting machine for speed and precision in manufacturing aerospace and medical products.

Tube extensions are available for loading tube stock to the maximum length of 80", or 6'8". The maximum part size is 52".

Our system solutions are flexible enough to produce small and large batches with diameters between 10 and 324 millimeters.

Lasertube makes it easy to customize parts according to the requirements of your customers.

We can complete your project in one facility with no downtime and extended lead times. We offer full-service center support that can:

Keep in mind that the traditional method for checking for twists or bows within the tube can take between five and seven seconds before cutting begins. Traditional touch sensing methods can be slow and inaccurate. While this may seem like a long time in the ageof fiber laser cutter, it is actually not that simple when working with tubes.

Fiber lasers have wavelengths of 1.06 microns. This wavelength is 10 percent lower than the CO2 laser beam. Fiber lasers have a much shorter wavelength which makes them more able to absorb reflective material. CO2 lasers are more likely reflect off these surfaces. Fiber laser cutting machines can be used to cut brass and copper as well as other reflective materials. The machine's laser beam, as well as the beam path, can be damaged by a CO2 laser beam reflected off the material. This risk is eliminated if the beam path is used with a fiber optic cable.

StarCut Tube L 600 may be purchased with either a fiber, USP or both lasers. StarCut Tube SL Compact Model has the smallest footprint.

The most productive solution for tubes of any section. Tubes up to Ø 6" (152.4 mm)2D cutCO2 or fiber laser

Whatever your customers' requests, with Lasertube you can recommend improvements to part design from the extensive library of connectionsfor assembling without screws or welds.

StarCut Tube L 600 is available with a fiber laser, a USP laser or both lasers. StarCut Tube SL is a compact model with the smallest footprint in the market.

This is the simplest and most effective way to get into the world of tube laser cutting. Tubes up O 4,72", (120 mm),2D cutFiber Laser