Tube Laser Cutting Systems 2018

Laser tube cutting machines do not have standard material towers. Bundle loaders provide the fastest method of handling tube material. One tube is fed from a bundle into the tube laser by a singularizing system. This type isn't able to feed open profiles like angles and channels. They interlock in the bundle and are not easy to get free. Step loaders can be used to sequence open profiles one by one into the machine, while still maintaining the proper orientation.

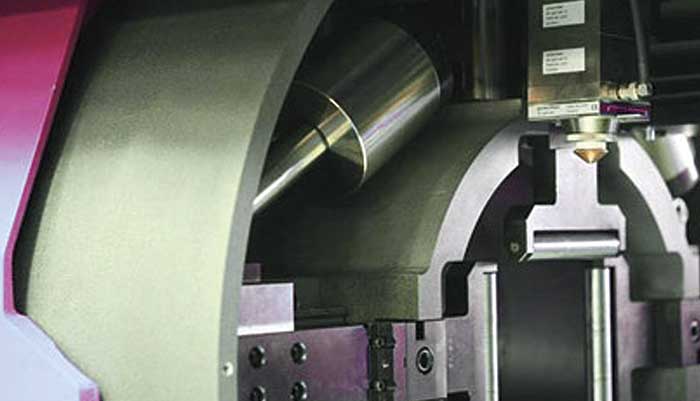

There are many ways to use processed tubes and profiles. It can be used in automotive, furniture design, architecture, and commercial vehicle construction. The laser-assisted processing (profiles and tubes) offers a wide range of manufacturing options and unique design possibilities in many industries.