Tube Laser Cutting Systems 3mm Mdf

Fiber lasers are practically maintenance-free and have superior wall plug efficiency to CO2 laser cutters. They can also cut reflective materials and provide precise cutting. They can also be used to cut certain metal thicknesses faster than CO2 machines. Speed is relative when it involves cutting tube. It is possible to reduce the time required for tube processing and produce finished parts faster.

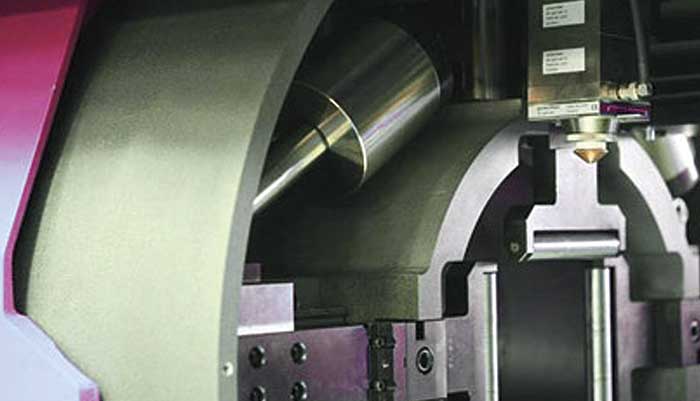

The CO2 reactor is larger and consumes more energy. To produce the laser beam, electricity is added to a mixture gas mixture. Mirrors are used to increase the intensity of light, and prepare it for exiting a resonator. The beam must travel through the path of several cooled reflectors until it reaches lens once it has left the resonance. This travel can cause a loss of power or quality in the laser beam.