Tube Laser Cutting Systems X-axis

Many believed fiber lasers could only work with thin materials. Because CO2 has a longer wavelength, it created enough material kerf to permit material removal. Fiber lasers can't produce the same level of kerf and results with thicker materials. This has been corrected by collimating tech, which can produce a wide fiber laser-generated beam that allows for materials separation. It also makes it possible to allow for material removal in thicker materials. You can also switch the beam width so that the machine can process thin materials with the narrower beam. This allows you to process more materials in a shorter time.

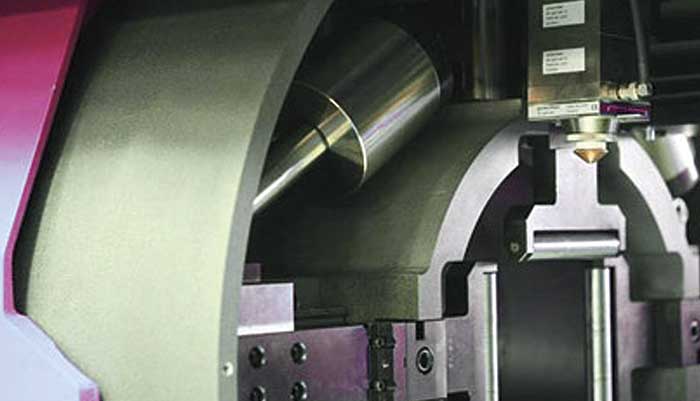

Micrometric Ltd uses its versatile Coherent StarCut tubes laser cutting machine in order to produce speedy and precise medical and aerospace products.