Head

Galvo heads can also be used to work at extremely high speeds when added to the machine. Galvo head are often used in portable laser-engravers.

FSL Muse Pandora (FSL) offers a variety of laser options, including 20W, 30W and 50W.

In an optical fiber laser, the light is bent by refraction. An optical fiber cable passes the light through an impurity-free transparent silica glass core. The core is covered with cladding, another layer of silica doped with added materials for lowering its refractive index. Because of their refractive index difference, the light will get refracted at the core-clad interface.

FSL Muse Pandora can operate with open lenses for 254mm,330mm, and420mm lenses. This allows the laser to be focused only on the work material.

They have a dedicated community website for their customers. Small communities are also active on Facebook groups.

They can also import and use file formats such as PLT, BMP and DXF.

Galvo heads can also be used to work at extremely high speeds when added to the machine. Galvo head are often used in portable laser-engravers.

FSL Muse Pandora (FSL) offers a variety of laser options, including 20W, 30W and 50W.

Fiber lasers can be expensive so if you are looking for a low-cost laser engraver, you should consider diode lasers.

You can import file types like PDF, SVG, JPG, BMP, and more into RetinaEngrave v3.0 from any CAD software of your choice.

Laser machines can cut any material. The type of laser machine you use will determine the material that can be cut. A CO2 laser machine is unable to cut through reflective materials like brass, copper, and aluminum. However, they can cut through nonmetallic material like wood and polymer.

Plasma can cut anything that is conductive, which pretty much means it can cut all kinds of metals. That includes reflective metals such as aluminum, copper, and brass (something laser machines struggle with).

Fiber lasers are very popular in engraving applications. They have wavelengths ranging from 780nm up to 2200nm.

Getting into the details of the operation cost of both laser and plasma is complicated. So I will write about that in another post.

The laser source module measures 8.3"x14.9" and the engraving machine module measures 13.8"x22".

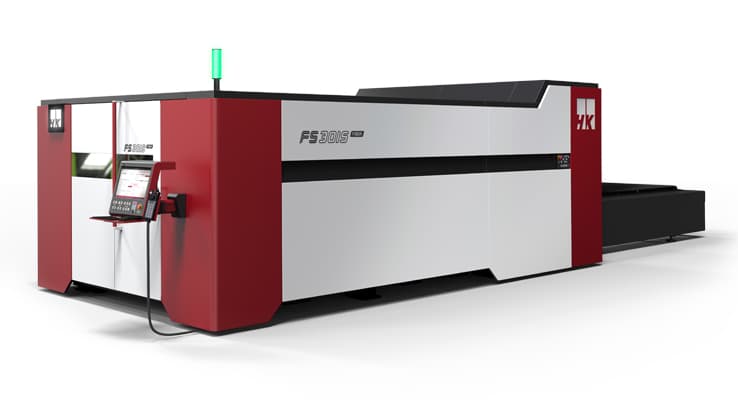

Our machines are capable to cut steel, brass or aluminum with no back reflections. These fiber laser machine will significantly reduce your maintenance requirements as well as your operating cost.

In fact, the diode module in a fiber laser typically outlasts other technologies by three times. Most lasers have a lifespan of about 30,000 hours, which equates to about 15 years of use. Fiber lasers have an expected life of 100,000 hours, which equates to 45 years of use.

Fiber lasers leave unsightly marks on wood.

The goal of any marking or engraving project is to create a readable mark, whether by hand or machine. Uncontrolled absorption, on the other hand, results in an uncontrolled mark on the wood.

Laser cutters cost between $13 and $20 per hour to operate. Water jet cutters cost between $15 and $30 per hour. Overall, the operating costs are comparable, and the total cost will be determined by your project.