Laser cutting can be achieved using high-power density energy from a focused laser beam. The CNC controller controls the laser generator to produce a high-frequency pulsed light beam in a controlled manner. This laser generates a beam of a specific frequency and width. The laser beam is transmitted through the optical path, reflected back into the optical path, and then focused by the focusing group. The focal point is located close to the surface to be cut. A small, high-energy, dense light spot forms on the part's surface. Material melts or vaporizes instantly. Each laser pulse creates a tiny hole in the substrate. The computer numerical controller controls the laser head and substrate to perform relative movement and dotting in accordance with the design file. This allows the substrate to be cut into the desired shape.

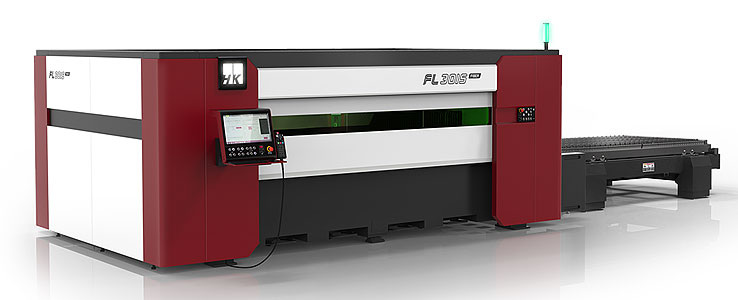

The maintenance-free, industrial-grade laser cutting system offers outstanding technical benefits, low power consumption, lower operating costs, repeatable and precise laser positioning performance. This sets new standards for complex pattern cutting and improves process quality inspection.