Can aluminium Be Laser Cut

The staff should be present at the site during the operation to assess the condition of the equipment. In an emergency, they must press the brake pedal quickly.

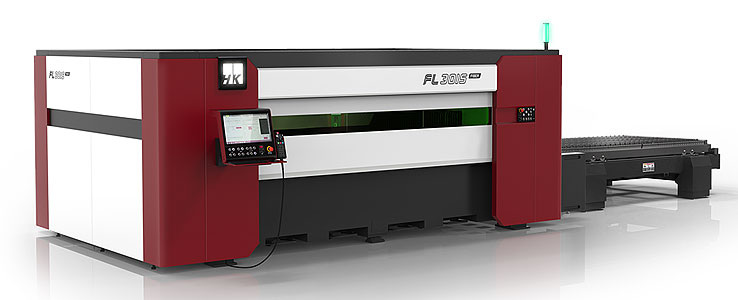

Fiber laser cutting systems can be used to cut various metal materials (sheet steels. metal tube. metal profile. 3D curved metals. and irregular metals). They are capable of cutting carbon steel, mild, stainless steel. spring steel. galvanized. aluminum, copper. gold. silver. alloy. titanium. iron. brass. manganese. chromium. nickel. cobalt. lead.