Can Laser Cutters Cut Glass

Today's products are being updated faster and faster. Due to the short product development cycle, there are more product diversity, sample trial production, and mass production. How to complete customer orders with quality and quantity, enhance corporate competition, and maintain corporate reputation is also every time. Therefore, the purchase of processing equipment with stable functions is the condition and foundation. Try to choose a brand with a high market share, a sound after-sales service system, a large number of after-sales service outlets, and a long-term shopping mall inspection. Greedy to buy low-quality products with low prices and no after-sales service, this will have a great negative impact on the processing of enterprises.

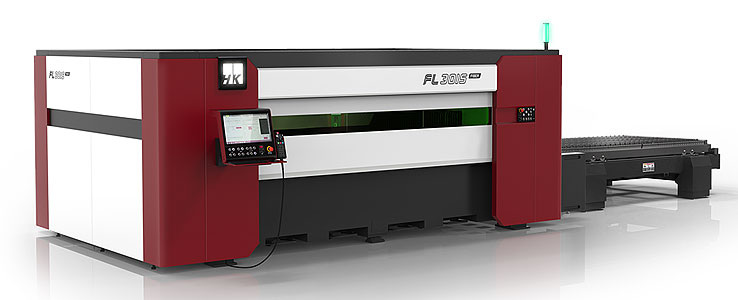

An affordable laser sheet-metal cutter starts at $6,800 with 300W of laser power. Some laser metal cutters cost from $19800 to $568,000 with laser fiber powers of 1000W or 1500W. Others are priced between $19,800 and $568,000 with laser laser powers of 1000W, 1500W and 4000W.