Laser Cutting Systems Zoominfo

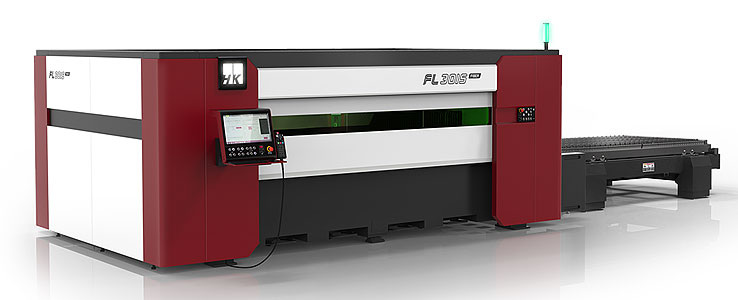

GSS Machinery has 2022 top-rated lazer cutting systems. These include 3 axis (3 axis), 4th Axis (rotary axis), 4, 5 axis, and 5Axis. All at a reasonable price. Get expert laser cutting support to match your 2D/3D laser cut ideas, plans, and projects.

Crystal laser cutters generate beams from Neodymium doped yttrium ortho vanadate. The wavelengths of these cutters are smaller as compared to CO2 laser cutters hence they can cut through some thicker materials.