Laser Cutting Machine 50w

With flame cutting, the material�s ignition temperature must be below the melting point. With high-alloyed steels and nonferrous metals, flame-cutting with oxygen is feasible but, for qualitative and economic reasons, it is not ideal.

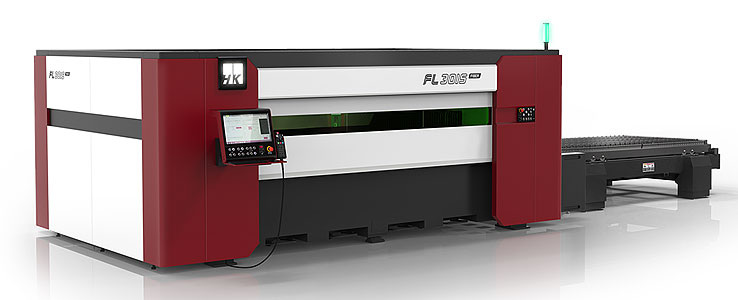

Laser cutting machines are divided into two types based upon laser sources: fiber laser machines and CO2 machine.