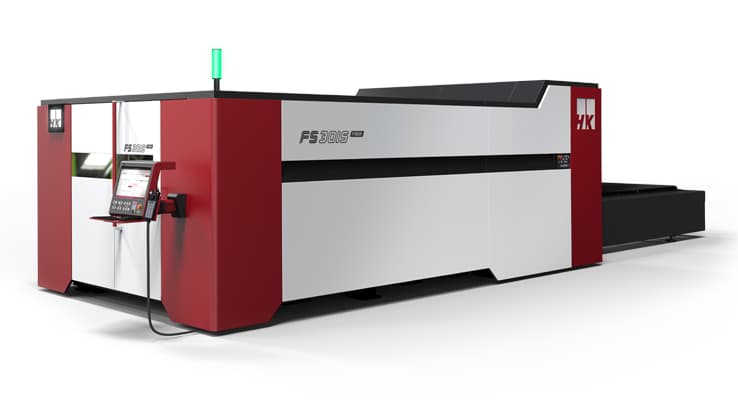

Precision Fabrication Machinery Finishing

High-quality laser metal cutting system that can be used to cut high-quality material. It's an excellent partner for metalworking and can be used to cut all kinds of materials. It can cut aluminum sheets/plates and metal tubes/pipes made in stainless steel, steel, electro steel, galvanized, aluminum zinc plate and aluminum, as well as aluminum, aluminum alloy, titanium alloy, copper and other metal materials.

We have designed and mass-produced front end components that allow for automated loading and discharging of wafers in between FOUPs and fab tools.