Iowa Precision

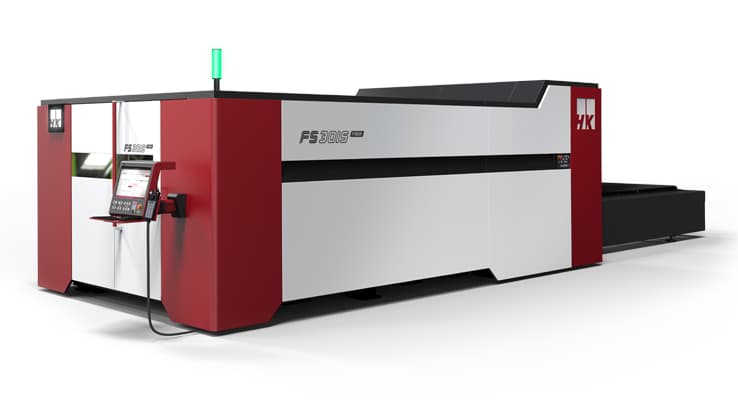

We live and breathe fabrication technology. We can spec, design, procure, and install the right machine for your needs.

Our large format five-axis machining and metal fabrication capabilities are unique and utilized around the globe for laboratory research, semiconductors, solar products, electronics, medical equipment and other demanding applications.