Wide Range

Our five-axis large format machining and metal fabrication capabilities make us unique. They are used worldwide for lab research, semiconductors and solar products as well as medical equipment and other highly demanding applications.

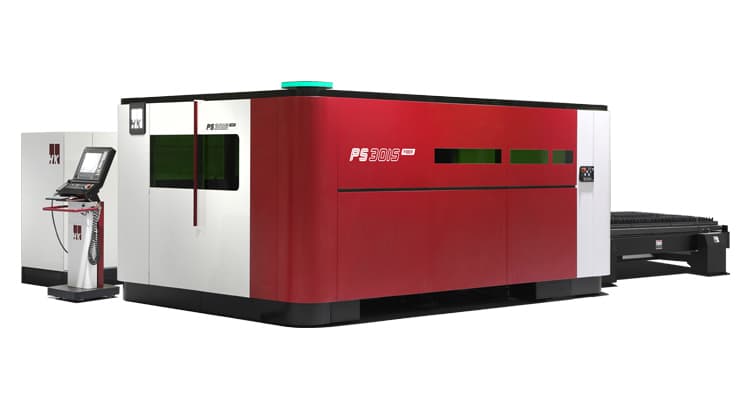

We only represent the best metal fabrication machinery on the market and only sell lines that we believe in.