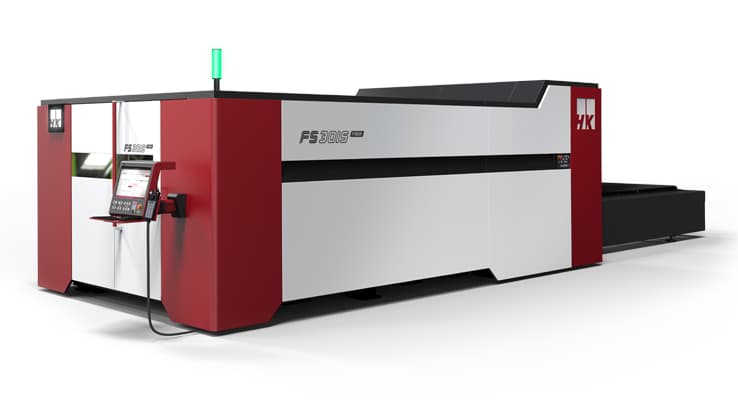

Precision Machine Fabrication Nc

Our CNC milling tool combines high speed and heavy-duty machine work to create complex shapes in a single set.

Gulf States Saw & Machine Co. provides custom welding and fabrication services. We can add value to fabrications and weldments with our CNC capabilities. GSS Machinery offers a turnkey solution that allows you to avoid the hassle of having to send the fabrication and machining to different suppliers.