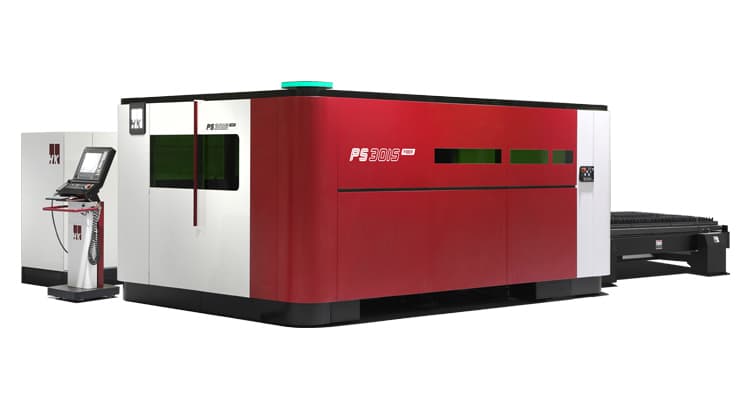

Precision Fabrication Machinery For Sale

Testimonial - I wanted to personally thank you for the outstanding sales, installation, follow-up and support of my new Trumpf 2030 Fiber laser and Liftmaster shuttle. The entire system works flawlessly. It was a pleasure to work with Eric and Gulf States Saw & Machine Co. during the purchase. But, even more, we are grateful for the continued support from Gulf States Saw & Machine Co.

GSS Machinery is a trusted solution provider for the manufacturing of equipment used in particle accelerator systems and cyclotron physics.