Industry

Our team will provide global supply chain solutions for your business to keep it running efficiently.

We are able and willing to do any job.

GSS Machinery has over 30 years experience and is dedicated to helping customers choose the right machine for their metal finishing processes. Our superior Micro-Finishing, Polishing, Buffing and Deburring solutions save time and money for our customers.

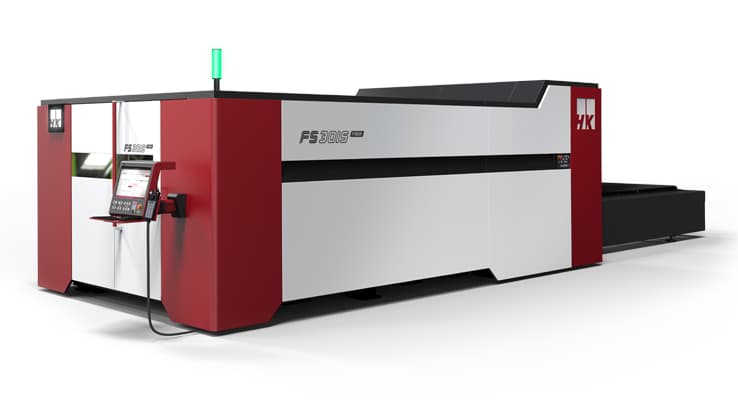

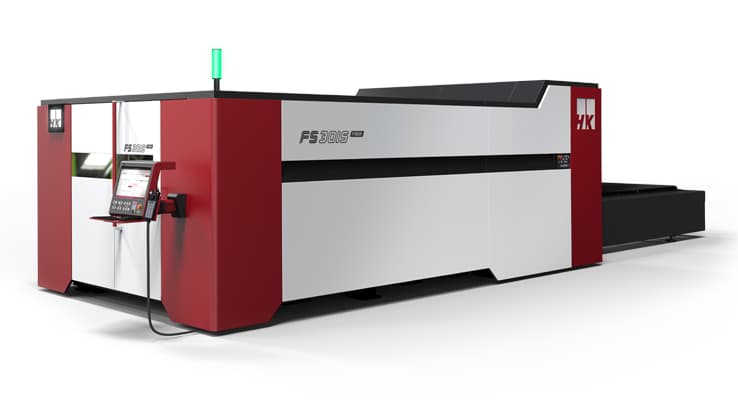

The productivity of metal fabrication firms and custom metal manufacturing businesses can be significantly increased by our fiber laser cutter machines.

International Technologies, Inc., a distributor of the most technologically advanced metal fabrication machinery, is driven by customers. We pledge to work with you business to provide the most advanced metal fabricating equipment today, and to support each purchase for the entire life of your product.

GSS Machinery optimizes vendor management through the use of our volume-leveraged suppliers network.

Our team will provide global supply chain solutions for your business to keep it running efficiently.

We are able and willing to do any job.

These tips and strategies will guide you in your search to find the perfect custom machine builder for your complex application.

We offer turnkey systems as well as high-level assemblies and electromechanical assembly for applications and industries that are complex.

Gulf States Saw & Machine Co. specializes in providing high-end precision fabrication machinery for metal fabrication in various industry applications. Our product offerings have been used by a wide range of metal fabrication industries, including automotive and aerospace.

Testimonial We have worked with Gulf States Saw & Machine Co.for many years. Don is an industry professional and works hard for customers. He is a highly knowledgeable metal industry professional and offers industry leading solutions."

We understand the demands of medical equipment production and can provide flawless manufacturing.

We would love to meet you and discuss your fabrication machinery needs. Our goal is to help your business grow, keep up technology, improve your product, and cut costs.

Gulf States Saw & Machine Co. provides the best and most efficient solution to organizing and storing sheet steel safely and efficiently.

Are you searching for a contract manufacturing partner? Our complete guide will help you avoid common pitfalls when selecting a contract manufacturing partner that suits your needs.

Cutting thick materials is difficult.

The less effective laser cutting becomes as the material thickness increases. For example, when it comes to cutting thick sheets of carbon steel, laser cutting may be difficult.

Thickness: A 40W to 45W CO2 laser, such as the Muse Core or 3D autofocus, can generally cut up to 14" thick wood, whereas a 90W tube laser, such as the P-Series PS24 or Muse Titan, can cut up to 12" thick wood.

Laser cutters can cut all types of metals, including mild steel, stainless steel, and nonferrous metals.