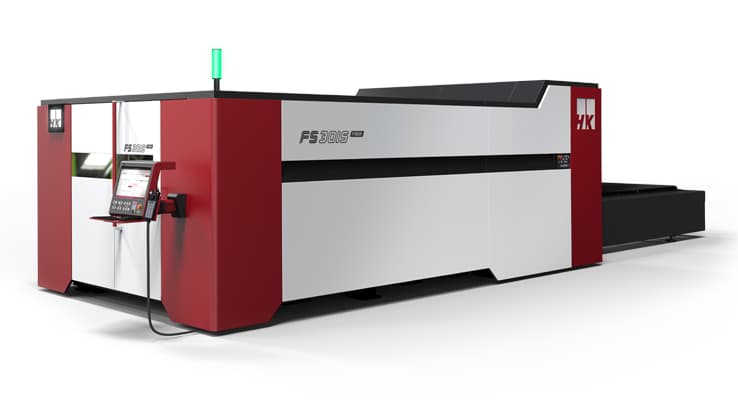

Precision Fabrication Machinery Xing

International Technologies, Inc., an independent distributor of highly-technologically advanced metal fabricating machinery, is customer-driven. We are committed to working with your company to provide the highest quality metal fabricating equipment, as well as to supporting every purchase until the end of the product's useful life.

Manufacturing medical equipment and instruments requires reliable automation solutions from a trusted partner.