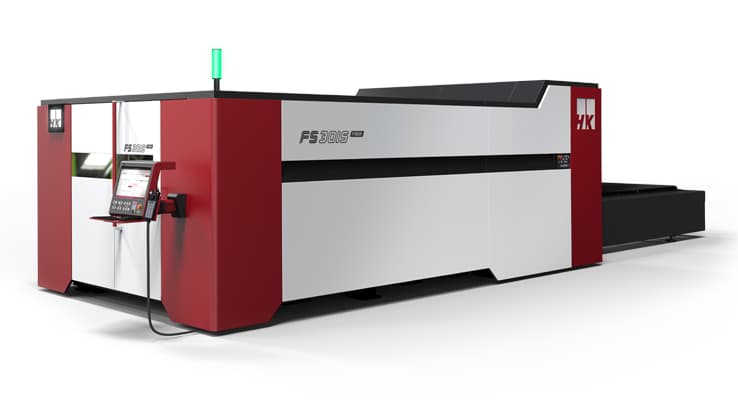

Precision Fabrication Machinery Virginia

GSS Machinery is aware that our customers have high stakes needs, from research and healthcare to national security. Our mission is to deliver equipment and components that can withstand extreme pressure. Our custom precision fabrication solutions meet the needs of demanding industrial applications that require complex manufacturing.

We offer a wide range of services including build-to print for systems, equipment, and assemblies.