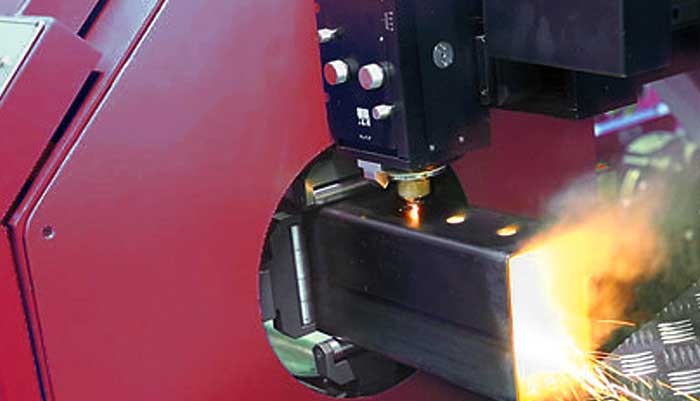

Tube Laser Cutting Systems 100w

Lasertube systems make it possible to create new applications or enhance existing ones. You can also enter new industries, increasing profits margins, and even entering new sectors.

Parts are held with automatic tabbing (done in FabCreator), and a set of jaws on the drive chuck and the idler chuck