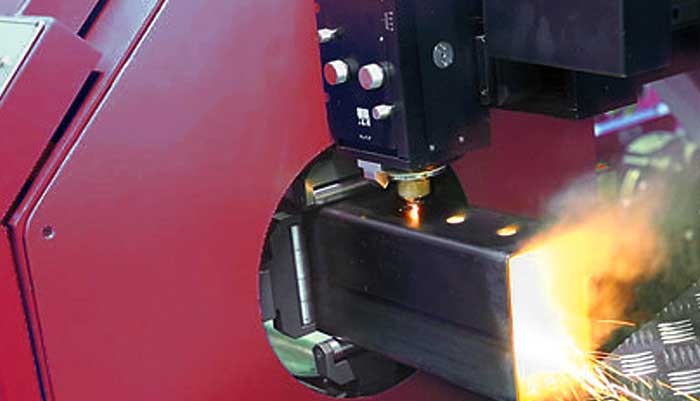

The CO2 solution to large-diameter tubes and profiles Tubes up O14" / 24", (355 mm, 610 mm).3D cutting modeCO2 laser

The fiber laser's small modules, which are compact and easily transportable, allow for redundancy. The resonator won't completely shut down if one module experiences a problem. In order to provide power for the down module, the fiber laser can temporarily produce more power until it is repaired. This can, of course, be done in the field. Sometimes, the fiber resonator will continue to produce reduced power until repairs are made. If a CO2 reactor has an issue, it can cause the whole resonator to go down.