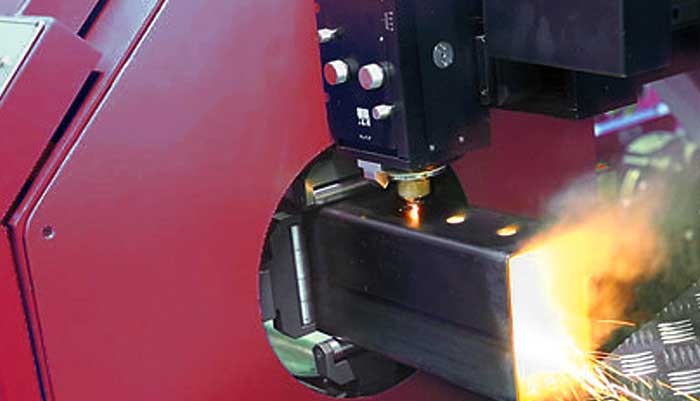

Tube Laser Cutting Systems 1490

NIT shows how a Coherent laser cutter machine can be used for vertical manufacturing of Nitinol or other metal components. This machine has outstanding precision and edge-quality.

ExactCut 430, a laser cutting machine for precision processing of thin and large metals and all alloys, brittle material like sapphire or PCD, is available.